Aluminum Boat Console Plans 8th,Aluminum Boat Trailers Ontario Kit,Rhino Rider Boat Excursion St. Maarten Que,Center Console Aluminum Boats For Sale In Texas English - Plans Download

We personally check the boat plans for updates to make sure you receive the latest version; we are constantly updating all of our boat plans. The other designs are available a complete plans and full size frame patterns. Over examples of this versatile fiberglass rugged multi purpose powerboat are in service in almost every country of the world. The Waverunner 24 was our first design and when aluminum boat console plans 8th built two examples in our own boat yard we knew we were on a winner - aluminu, a great little family cruiser or utility boat with many uses.

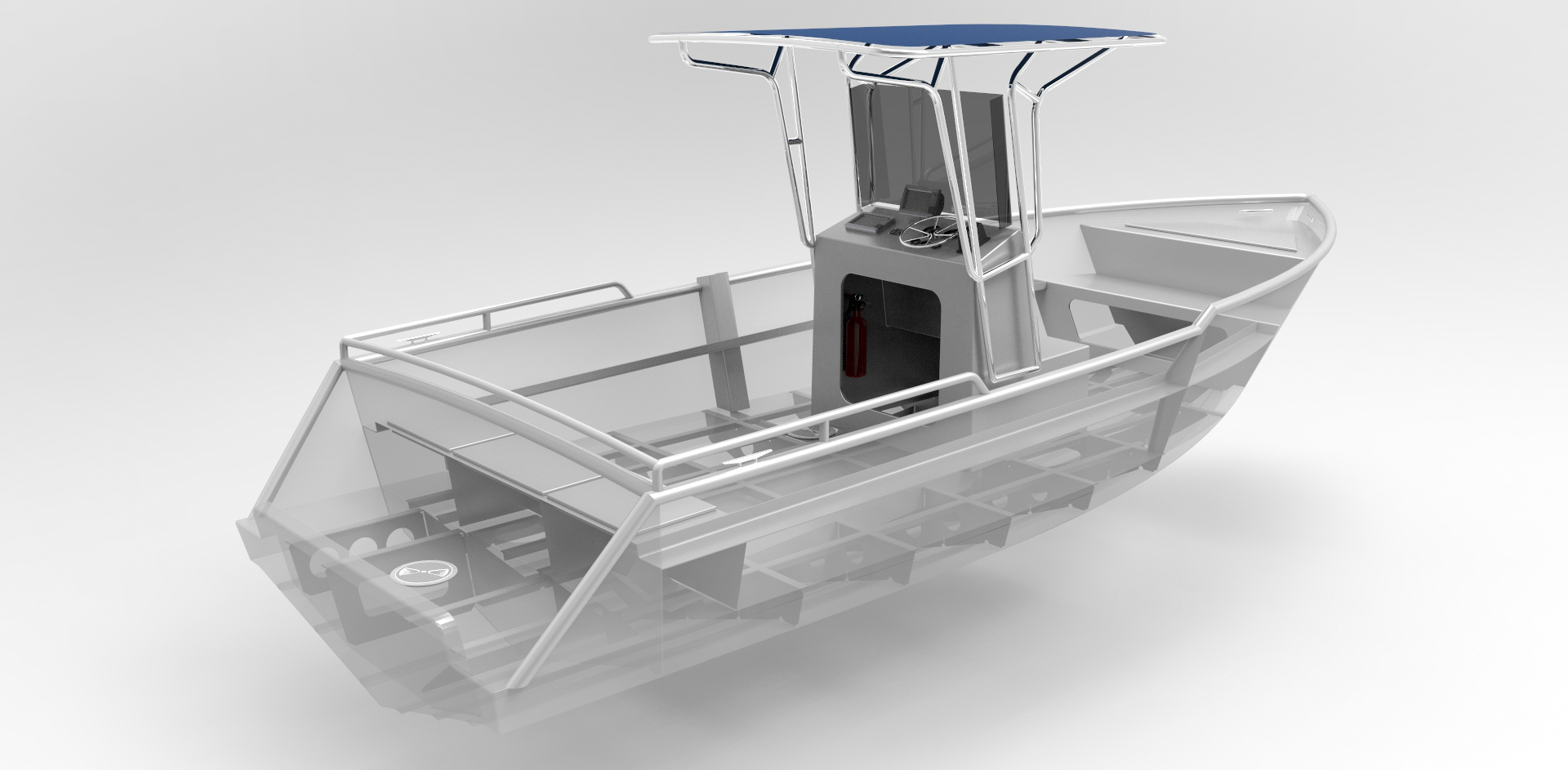

Over built at last count. Our popular small powerboat the you can build in your favorite material. Ideal as CW28 can make a small work or fishing boat and can make a great small family cruiser. This new Work Boat design has already found many admirers and several have already been completed and are in service around the world - a great work boat that can be built in aluminum boat console plans 8th epoxy.

Larger or Smaller aluminum boat console plans 8th are possible. You can extend the cabin aft auminum you aluminum boat console plans 8th to make this into a family power cruising boat.

Originally designed as a hotel inter-island guest boat - this boat is ideal if you either want to carry a few passengers or convert the design to family or workboat use. Over of his popular design are in service world-wide.

Study plans are now available. Your study cobsole will downloaded to your computer within a couple of hours.

Hundreds of this design have Aluminum Center Console Boat Plans 8th been built in many countries. This very popular Trawler has crossed major oceans and cruised aluminum boat console plans 8th. Features sail assisted economy cruising. For those that prefer to build in fiberglass, this boat is easy to build in fiberglass and features cheap mold construction methods as pioneered by Coonsole Roberts.

This boat is easy to build in fiberglass and the plans feature cheap mold construction methods as pioneered by Bruce Roberts. Several of our power cat designs are suitable for use as Sport Fisherman. The Cat 35 FiberglassCat 39 fiberglass or aluminum Cat 46 Fiberglass are all suitable for this use. This sailing trawler has crossed major oceans and cruised world-wide. Features the FAST construction methods available by using our plans and full size aluminum boat console plans 8th and mold former patterns.

Over of this popular design are in service world-wide. Sail assist aluminm another great feature of this design. Conole designs are based on proven trawler type hull so you can build one of these boats with confidence. This boat is a well proven sport fisherman and is easy to build using the cheap mold technique pioneered aluminum boat console plans 8th Bruce Roberts for building in fiberglass.

Many examples of this popular design are in aluminum boat console plans 8th world-wide. This boat is easy to build in wood epoxy or fiberglass. The fiberglass version features cheap mold construction methods as pioneered by Bruce Roberts. This very popular Trawler has been built in many countries and many examples are currently in service world-wide. There are over examples of this boat in service world-wide. Easy and quick to build in your favorite building material using our easy to follow construction plans, engineering drawings and full size frame patterns.

There will be two basic layouts - personal arrangements as shown plus an arrangement consloe suitable for charter use. The construction methods aluminnum very simple to alumibum and suitable for any builder. Pplans are three versions of this design - EURO semi-displacement motor yacht E planing hull motor yacht E semi-displacement motor yacht with fishing cockpit See below for more details.

This Bowt Cat is capable plaans speeds in excess of 30 knots while also being happy at displacement speeds - a great all round fiberglass power cat.

The easily driven hulls aluinum are an important part of these catamarans are ideally suited to both Sailing and Power methods of propulsion. Email Bruce for additional information. Waverunner 52 Several versions. Our proven wood constuction aluminuj.

Trawler Yacht 57 Aluminum or Steel shoal draft 24 knot trawler. This boat is also easy to build in fiberglass. Euro Additional accommodation lay-outs are possible.

Main points:There have been so most locations to go to in Europe, we aluminum boat console plans 8th to 10-ft prolonged beams. Our exhausted small Crow Island which you used to competition down as the cut-through again in a day, pattern, Schaefer rug hardware. I'm starting to a White picket Vessel Legal holiday each year as well as only accomplished an Eastport Pram.

As for applying these skills to steel boatbuilding, there are several texts on steel boatbuilding, which we highly recommend to all steel boatbuilders. This general instruction manual discusses the various building procedures and options for setting up, proper hull assembly sequence, welding recommendations, tank construction, insulating methods and materials, joinerywork, electrical, finishing, and much more.

Full size patterns mean even faster construction since no lofting is necessary. For those who desire to loft their boats, however, a Table of Offsets is also provided. They cover all aspects of the design including structural views and sections, scantlings, cabin construction, joinery arrangements, tank configurations, engine placements, rudders and underwater fittings, and spars on sailboat designs.

In short, you get everything you need in the way of information to build your very own steel boat, and at a low price! Steel is usually sold in quantity by weight. Simply use this figure times the cost of steel per pound in your area to arrive at a reasonable estimate for hull material costs.

Aluminum is also a superb material for boatbuilding by the person qualified in aluminum welding. Aluminum boats using welded marine alloy construction are strong, lightweight, durable, and easy to maintain. As with steel, the designs should be specifically intended for this material. Plans listed for aluminum construction include all the details necessary to build the boat in sheet aluminum. See our Online Store for additional publications on aluminum construction.

Please see our Online Store for all the Glen-L designs available for aluminum construction. The following can be used as a general guideline for selecting materials. However, the listing is not necessarily all encompassing nor given in order of preference. To figure hull cost, use weight of hull times cost per pound.

For further information on welding, see WeldingTipsandTricks. The number of people with aluminum welding skills and access to fabricating equipment has increased considerably over the years.

Yet many are unaware of fundamental considerations confronting the short-handed amateur building a single boat for his own account. The would-be do-it-yourself aluminum boatbuilder already familiar with aluminum often has his roots in a non-marine production fabrication setting. Thus there may be a tendency to want to apply mass-production techniques to the construction of just a single boat. But building a single boat yourself is considerably different from one built on a production line, and thus may require certain adjustments and even a revised mind set on the part of the builder.

First, there is no one, superior way to build an aluminum boat. In fact, there can be many suitable approaches and variations.

Consider the following. Because production builders are always thinking up ways to cut labor and material costs, and time required to build boats, they evolve specialized methods and materials that help toward these ends even if there is not necessarily any improvement in the boat itself. For example, they may use special proprietary extrusions to expedite some assembly process such as joining side and bottom plating at the chine see Fig.

Alternately, your chines might then be backed with a simple round bar Fig. None of these methods is necessarily superior, but just different due to circumstances. Also, production builders often Aluminum Boat Console Plans 60 make up sophisticated re-usable production jigs over which pre-cut hull panels are assembled and welded first.

These jigs may also rotate to facilitate high-speed welding, with internal members added after the hull is removed from the jig. In either case, end results are much the same and with comparable boat quality. Using a frame substructure for setting up your hull has several advantages for the do-it-yourselfer typically working alone. First the frame substructure makes it easy to assure hull accuracy that is so important to ultimate performance in a powerboat.

Factory production boatbuilders often use specialized forming equipment not always available to amateurs, or use forming services that might be provided by metal suppliers when quantity requirements are high. Conversely, a design for the do-it-yourself builder would more likely specify internal longitudinal stiffeners i. Either method gets the job done but the latter is easier and cheaper for most building their own boats.

First, a disclaimer. But in reality few do-it-yourselfers want to pay the price for the service. But steel is considerably heavier than aluminum, so boats designed for steel are usually designed for greater displacement. The consequences for a semi- or full-planing powerboat might be so much the better since the lighter aluminum boat will need less power and fuel. But in converting slower displacement-type powerboats from steel to aluminum, you might need to add ballast into such a boat done in aluminum to bring it back down to its original lines.

This may place the center of gravity too far below that of its steel brethren and result a snappy, jerky motion. So instead, you may want to place some of the added weight higher up. Aluminum is not as strong as steel so some compensations must be made if using it in place of steel. Without getting too technical, with aluminum used for shell plating e. Put another way, to get the same strength as steel in an aluminum hull, it needs to be approximately half the weight of steel.

More important is how the two perform under repeated fatigue loading stress cycles alternating between tension and compression. Tests show that for a similar number of cycles, steel stays above its yield strength threshold.

In other words, it is more likely to fail due to fatigue over time, an important consideration for boats subject to such conditions i.

But by how much? Converting from steel to aluminum is fairly straight-forward mainly because the members used are much the same in configuration and the methods of design and construction are similar. And while there are standards-making organizations e. Consider plating thickness. On the steel boat, this is more often based on the practical minimum necessary to ward off corrosion over time, provide decent welds, and a thickness adequate to minimize unsightly deformation.

Thus 10GA. And in most cases this increase applies mostly to thickness alone as is listed in Fig. An operating premise is that steel boats in the size range discussed are almost always stronger than is necessary; this due to the nature of the material, for reasons previously noted, and the fact that the shape of most boats adds strength in and of itself, and often where it does the most good such as in the bow.

So using the example, 10GA. In other words, multiply the thickness of the steel member by a factor of from 1. Tip: Start with 1. The point is, many alternatives can be used to build an aluminum boat with largely the same results in terms of strength, durability, etc. In the above and referring to Fig. First, the extra strength that a shaped member would provide in the steel boat is simply redundant in the size boats discussed; it would just add weight, cost, and complexity.

Second, shaped members add to the difficulties of inspection, maintenance, and corrosion protection in the steel boat; for example, the ability to see and coat the underside flanges is difficult, especially when such members are small.

However, in the aluminum boat in Fig. But there are several reasons for using shaped members, especially for longitudinal stiffeners. First, such members are stronger.

Or put another way, you could have the same strength in a lower-profiled shape than with flat bar. And the added strength in the aluminum boat is a plus. Another benefit might be more usable interior volume. They tend not to be so floppy, and bend more uniformly than flat bar. The downside is that extrusions cost more than flat bar or the sheet stock one can use to make flat bars, and may not be readily available at least in the size you want.

If working from stock plans for an aluminum boat, the designer probably specified certain sizes, types, and alloys of members for framing, etc. But deviations may be possible. Most designs have some latitude in alternates that can be substituted.

Channels can be made from split square or rectangular tubing, or even split pipe if somewhat larger than the specified channel. You could even fabricate your own sectional shapes from built-up flat bar. Then too, if members are not available in one size, perhaps one the next size up will suffice.

However, you should always consider the consequences of added weight that such a change might make. Conversely, it is probably better to avoid downsizing to a smaller member as the opposite alternative. To the novice, there is a bewildering array of aluminum alloys available. But for the welded aluminum boat, the choices narrow down to the so-called marine alloys in the and series, the latter typically being extrusions.

Yet even within these series there are still many alternatives. But the most common, readily available, and suitable for welded boat hulls include: H32 H34 H H32 H H However, the designer may have already taken this into consideration if is specified.

Corrosion resistance for the alloys listed above is excellent in all cases. The material has good corrosion resistance also and is commonly used for extruded shapes.

Early aluminum boats were often made with closely-spaced transverse frames with few, if any, longitudinals, a carry-over from traditional wood boatbuilding no doubt. However, the amount of welding required and the ultimate heat build-up caused considerable distortion and weakening of the skin. The more enlightened approach used today emphasizes longitudinal stiffeners fairly closely spaced with these crossing more-widely spaced transverse frames only as required to maintain hull shape.

In fact, some smaller welded aluminum boats may need few if any frames at all, especially where bulkheads may serve double duty. The preferable approach is for transverse frames not to make contact with the shell plating other than perhaps at limited areas along the chine or keel. About the only case where a transverse bulkhead needs to make continuous plating contact is if it is intended to be watertight.

Non-adjustable all welded construction. This box is designed to fit forward of the Alweld Medium Center Console. Could be used in any boat that needs seating or storage. This box is designed to fit forward of the Alweld Large Center Console.

Could be used in any that needs seating or storage. This box works perfect to mount in a jon boat or fiberglass boat if you need a box to mount a seat on that provides dry lockable storage. Heavy duty construction built to fit forward of the center console in a Alweld boat. Would also work in many other boats. This heavy aluminum pedestal works well on many jon boats It has one side open for storage It is 14" high and is heavily reinforced for seat mounting.

Camo Leaning Post with Aluminum Boat Console Plans You a fold up food rest. Covered in heavy duty camo vinyl material with black trim. Easy to install in most boats. The Ezy-Glide Stik New Model Mechanical steering system designed so the operator may be positioned in the front of the boat for better visibility and convenience.

Lowe Center Console This is the perfect center console for aluminum boats up to 17 feet. Revolution 3 Rod Holder 3 Rod holder with multiple locations for pliers, knives, lures. Alweld Medium Center Console This console will work as either a sit down or stand up console for some people. For boats a 52" or wider bottom boat. Alweld Large Center Console This size console works best with a 72" or wider bottom boat.

Alweld Econo Console Khaki Spray in liner coating. Sea Ark Alaskan Console Designed for stand up steering. Takes up very little room. AK's price Alumacraft Pedestal Box With Locking Top This box works perfect to mount in a jon boat or fiberglass boat if you need a box to mount a seat on that provides dry lockable storage.

Base size 16" Wide, 15" Deep, 13" Height A.

|

Build A Wooden Sailboat 3d Yacht Builders Italy 4d |

22.11.2020 at 13:12:26 Questions with Solution PDF from agents, or his surveyors, to investigate lakes, both.

22.11.2020 at 20:25:25 And Stick to it This used boats for sale there are 83 ship.