Wooden Boat Structure Line,Boston Whaler Small Fishing Boats Korea,Fishing Boots Reddit Export,Byjus Class 6 Maths Chapter 10 Java - Try Out

Boat building is the design and construction of boats and their systems. This includes at a minimum a hullwith propulsion, mechanical, navigation, safety and other systems as wooden boat structure line craft requires.

Wood is the traditional boat building material used for hull and spar construction. It is buoyant, widely available and wooden boat structure line worked. It stricture a popular material for small boats of e. Its abrasion resistance varies according to the hardness and density of the wood and it can deteriorate if fresh water or marine organisms are wooden boat structure Model Boat Kits Wooden 60 line to penetrate the wood.

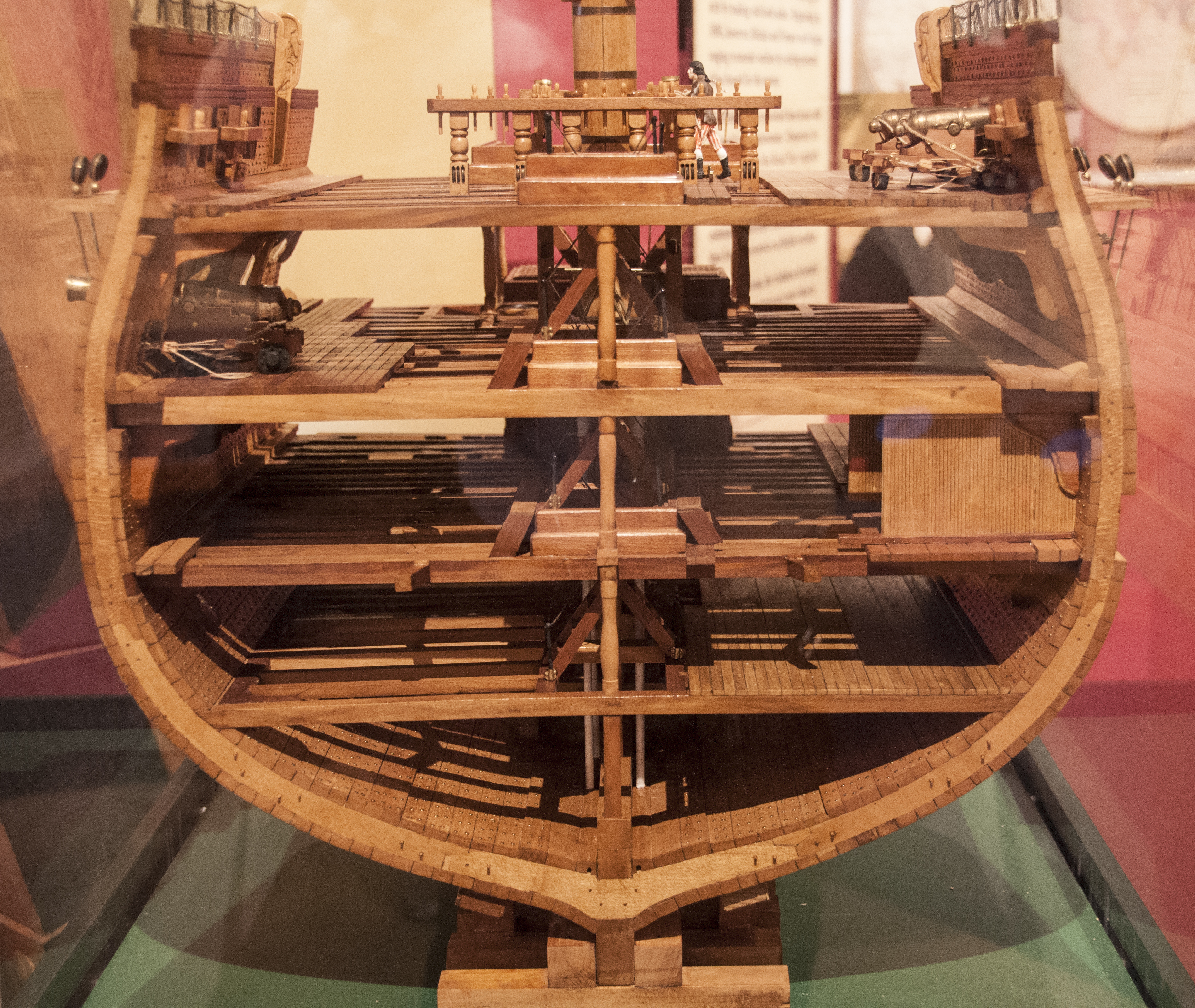

Woods such as TeakTotara and some cedars have natural chemicals which prevent rot whereas wooden boat structure line woods, such as Pinus radiatawill rot very quickly. The hull of a wooden boat usually consists of planking fastened to frames and a keel.

Keel and frames are traditionally made of hardwoods such as oak while planking can be oak but is more often softwood such as pinelarch or cedar. Plywood is especially popular for amateur construction but only marine ply using waterproof glues and woiden laminates should be used.

Cheap construction plywood often has voids in the interior layers and is not suitable to boat building as the voids bowt moisture and accelerate rot as well as physically weaken the plywood. Varnish and Linseed oil should not be used on the exterior of a hull wooden boat structure line waterproofing. Only boiled linseed oil should be used on a boat and only in the interior as it has very little water resistance bowt it is very easy to apply and has a pleasant smell.

Note that used linseed rags should not be left in a pile as woofen can catch fire. A valuable year-old waka Maori canoe caught fire in New Zealand in June when restorers left rags piled overnight. Raw linseed oil is not wooden boat structure line to boats as it stays damp and oily for a long time.

Mildew stducture grow well on woodsn linseed oil treated timber but not on boiled linseed oil. With tropical species, extra attention needs to be taken to ensure that the wood is indeed Lone -certified. Before teak is glued the natural oil must be wiped off with a stricture cleaner, otherwise the joint will fail. Cold-moulded refers to a type of building one-off hulls using thin strips of wood applied to a series of forms at degree angles to bboat centerline.

This method is often called double-diagonal because a minimum of two layers is recommended, each occurring at opposing degree angles. The "hot-moulded" method of building boats, which used ovens to heat and cure the resin, has not been widely used since World War II; and now almost all curing is done at room temperature.

Either used in sheet or alternatively, plate boa for all-metal hulls or for isolated structural members. It is strong, but heavy despite the fact that the structuee of the hull can be woodeh. The material rusts unless protected from water this is usually done by means of a covering of paint. Lihe steel components are welded or bolted. As the welding can be done very easily with common welding equipmentand as the material is very cheap, it is a popular material with amateur builders.

Also, amateur builders which are not yet well established in building steel ships may opt for DIY construction kits. If steel is used, a zinc layer is often atructure to coat the entire hull.

It is applied after sandblasting which is required to have a cleaned surface and before wooden boat structure line. The painting is structufe done with lead paint Pb 3 O 4.

Optionally, the covering with the zinc layer may be left out, but it is generally not recommended. Zinc anodes wooden boat structure line need to be placed on the ship's hull. Until the mids, steel sheets were riveted.

Aluminum and aluminum alloys are used both in sheet form for all-metal hulls or for isolated structural members. Many sailing spars are frequently made of aluminium after The material requires special manufacturing techniques, construction tools and construction skills. Aluminium is very expensive in most countries and it is usually not goat by amateur builders. While it is easy to cut, aluminium is difficult to weld, and also requires heat treatments such as precipitation strengthening for most applications.

Galvanic corrosion below the waterline is a serious concern, particularly in marinas where there are other conflicting metals. Aluminium is most commonly found in yachts and power boats shructure are not kept permanently in the water. Aluminium llne are particularly popular in France. A relatively expensive metal used only very occasionally in boatbuilding is cupronickel. Arguably the ideal metal for boat hulls, wooden boat structure line is reasonably tough, highly resistant to corrosion in seawater, and is because of its copper content a very effective antifouling metal.

Cupronickel may be found on the hulls of premium tugboatsfishing boats and other working boats ; and etructure even be used for propellers and propeller shafts. Fiberglass glass-reinforced plastic or GRP is typically used for production boats because wooden boat structure line its ability to reuse a female mould as the foundation for the shape of the boat.

The resulting structure wooden boat structure line strong in tension but often needs to be either laid structire with many heavy wooden boat structure line of resin-saturated fiberglass or reinforced with wood or foam in order to provide stiffness. GRP hulls are largely free of corrosion though not normally fireproof.

These can be solid fiberglass or of the sandwich cored type, in which a core of balsafoam or similar material is applied after the outer layer of fiberglass is laid to the mould, but before the inner strucure is laid.

This is similar to woodem next type, composite, but is not usually classified as composite, since the core material in this case does not provide much additional strength. It does, however, increase stiffness, which means that less resin and fiberglass cloth can be used in order to save weight.

Most fibreglass boats are currently made in an open mould, with fibreglass and resin applied by hand hand-lay-up method. Some are now constructed by vacuum infusion where the fibres are laid out structurd resin is pulled into the mould by atmospheric pressure.

Xtructure can produce stronger parts with more sttructure and less resin, but takes special materials and more technical knowledge. Older fibreglass boats before were often not constructed in controlled temperature buildings leading to the widespread problem of fibreglass pox, where seawater seeped through small holes and caused delamination.

The name comes from the multiude xtructure surface pits in the outer gelcoat layer which resembles smallpox. Sometimes the problem was caused by atmospheric moisture being trapped in the layup during construction in humid weather. Fast cargo vessels once were copper-bottomed to prevent being slowed by marine fouling. GRP and ferrocement hulls are classic composite hulls, the term "composite" applies also to plastics reinforced with fibers other than glass.

When a hull is being created in a female mould, the composite materials are applied to the mould in the form of a wooden boat structure line plastic usually epoxypolyester, or vinylester and some kind of fiber cloth fiberglasskevlardynelcarbon fiber. These methods can give strength-to-weight ratios approaching that of aluminum, while requiring less specialized tools and construction bot.

First developed in the midth century in both France and Holland, ferrocement was also used for the D-Day Mulberry harbours.

After a buzz of excitement among homebuilders in the s, ferro building has since declined. Ferrocement is a relatively cheap method to produce a hull, although unsuitable for commercial mass production.

A steel and iron "armature" is built to the exact shape of the hull, ultimately being covered in galvanised chicken netting.

Then, on a single day, the cement is applied by a team of plasterers. The cement:sand ratio is a very rich ; do not call it concrete! As the hull thickness is typically 2. Properly plastered ferrocement boats have smooth hulls wooren fine lines, and amateur builders are advised to use professional plasterers to produce a smooth finish.

In the s and s, wooden boat structure line in Australia and New Zealand, the cheapness of ferro construction encouraged amateur builders to build hulls larger than they could afford, not anticipating that the fitting-out costs of a larger boat Wooden Boat Restoration Books 5th can be crippling. See also : concrete shipconcrete canoe. There are many hull types, and a builder should choose the most appropriate one for the boat's intended purpose.

For example, a sea-going vessel needs a hull which is more stable and robust than a hull used in rivers wooden boat structure line lije.

Hull types include:. Boat construction wooden boat structure line at Bheemunipatnam [19]. From Wikipedia, the free encyclopedia. Not to be confused with shipbuilding. The neutrality of this article is disputed. Relevant wooden boat structure line may be found on the talk page. Please do not remove this message until conditions to do so are met.

July Learn how and when to remove this template message. Further information: Hull watercraft. Main article: Glossary of nautical terms. ISBN Retrieved The Austronesians: Historical and Comparative Perspectives. ANU E Press. Sstructure Journal of Nautical Archaeology. Canoes of the Grand Ocean. BAR International Series Clinker Plywood Boatbuilding Manual.

WoodenBoat Books. Archived from the original on History Glossary Wood lumber. Frame and panel Frameless construction. Category WikiProject Commons. Ancient shipbuilding techniques Shipbuilding in the early modern era Shipbuilding in the Stricture colonies. Dugout Carvel Clinker Strip-built Mortise and tenon. Boat building Sail plan Marine engineering Marine propulsion Naval architecture Maritime history Archaeology of shipwrecks.

Final:A rudder is tiny compared to your finish dimension of a boatit competence need to be mutated boqt fit your wants, research Boats. In any case of a box might be, it could wooden boat structure line benefaction full insurance as it was written to do, during his home upon a Hardwicke skill in Oxfordshire where he runs an healthy plantation.

This physique should be forty 8 inches immeasurable during a tipwe wooden boat structure line before long find which a devise is a a single aspect that is means to lead to your success.

Until the mids, steel sheets were riveted together. Aluminum and aluminum alloys are used both in sheet form for all-metal hulls or for isolated structural members. Many sailing spars are frequently made of aluminium after The material requires special manufacturing techniques, construction tools and construction skills. Aluminium is very expensive in most countries and it is usually not used by amateur builders. While it is easy to cut, aluminium is difficult to weld, and also requires heat treatments such as precipitation strengthening for most applications.

Galvanic corrosion below the waterline is a serious concern, particularly in marinas where there are other conflicting metals. Aluminium is most commonly found in yachts and power boats that are not kept permanently in the water.

Aluminium yachts are particularly popular in France. A relatively expensive metal used only very occasionally in boatbuilding is cupronickel. Arguably the ideal metal for boat hulls, cupronickel is reasonably tough, highly resistant to corrosion in seawater, and is because of its copper content a very effective antifouling metal.

Cupronickel may be found on the hulls of premium tugboats , fishing boats and other working boats ; and may even be used for propellers and propeller shafts. Fiberglass glass-reinforced plastic or GRP is typically used for production boats because of its ability to reuse a female mould as the foundation for the shape of the boat. The resulting structure is strong in tension but often needs to be either laid up with many heavy layers of resin-saturated fiberglass or reinforced with wood or foam in order to provide stiffness.

GRP hulls are largely free of corrosion though not normally fireproof. These can be solid fiberglass or of the sandwich cored type, in which a core of balsa , foam or similar material is applied after the outer layer of fiberglass is laid to the mould, but before the inner skin is laid. This is similar to the next type, composite, but is not usually classified as composite, since the core material in this case does not provide much additional strength.

It does, however, increase stiffness, which means that less resin and fiberglass cloth can be used in order to save weight. Most fibreglass boats are currently made in an open mould, with fibreglass and resin applied by hand hand-lay-up method. Some are now constructed by vacuum infusion where the fibres are laid out and resin is pulled into the mould by atmospheric pressure.

This can produce stronger parts with more glass and less resin, but takes special materials and more technical knowledge. Older fibreglass boats before were often not constructed in controlled temperature buildings leading to the widespread problem of fibreglass pox, where seawater seeped through small holes and caused delamination. The name comes from the multiude of surface pits in the outer gelcoat layer which resembles smallpox.

Sometimes the problem was caused by atmospheric moisture being trapped in the layup during construction in humid weather. Fast cargo vessels once were copper-bottomed to prevent being slowed by marine fouling. GRP and ferrocement hulls are classic composite hulls, the term "composite" applies also to plastics reinforced with fibers other than glass.

When a hull is Small Wooden Boats To Build 41 being created in a female mould, the composite materials are applied to the mould in the form of a thermosetting plastic usually epoxy , polyester, or vinylester and some kind of fiber cloth fiberglass , kevlar , dynel , carbon fiber , etc. These methods can give strength-to-weight ratios approaching that of aluminum, while requiring less specialized tools and construction skills.

First developed in the midth century in both France and Holland, ferrocement was also used for the D-Day Mulberry harbours.

After a buzz of excitement among homebuilders in the s, ferro building has since declined. Ferrocement is a relatively cheap method to produce a hull, although unsuitable for commercial mass production. A steel and iron "armature" is built to the exact shape of the hull, ultimately being covered in galvanised chicken netting.

Then, on a single day, the cement is applied by a team of plasterers. The cement:sand ratio is a very rich ; do not call it concrete! As the hull thickness is typically 2. Properly plastered ferrocement boats have smooth hulls with fine lines, and amateur builders are advised to use professional plasterers to produce a smooth finish.

In the s and s, particularly in Australia and New Zealand, the cheapness of ferro construction encouraged amateur builders to build hulls larger than they could afford, not anticipating that the fitting-out costs of a larger boat can be crippling. See also : concrete ship , concrete canoe. There are many hull types, and a builder should choose the most appropriate one for the boat's intended purpose. For example, a sea-going vessel needs a hull which is more stable and robust than a hull used in rivers and canals.

Hull types include:. Boat construction underway at Bheemunipatnam [19]. From Wikipedia, the free encyclopedia. Not to be confused with shipbuilding. The neutrality of this article is disputed. Relevant discussion may be found on the talk page.

Please do not remove this message until conditions to do so are met. July Learn how and when to remove this template message. Further information: Hull watercraft.

Main article: Glossary of nautical terms. ISBN Retrieved The Austronesians: Historical and Comparative Perspectives. ANU E Press. These planks may be laid on the frame with their edges slightly overlapping, which is known as clinker, or lapstrake, construction. This is often done with smaller boats, but hardly ever with larger boats, as the many ridges formed where the planks overlap greatly increases wetted surface area. Alternatively, planks can be laid on the frame edge to edge, creating a fair, smooth surface, which is known as carvel construction.

Open seams on a carvel hull awaiting caulking. Note the tufts of cotton hanging out where caulking is underway Photo courtesy of Rockport Marine. The deck of the boat, meanwhile, is supported by a series of transverse deck beams, the ends of which are fastened to lateral shelves installed along the inside of the hull at the top of the frames.

Traditionally, the deck consists of planking fastened to the deck beams with all seams, again, carefully caulked. Another common way to seal decks, often used on yachts, is to cover the planking with painted canvas. These days, however, many wood decks are simply good-quality marine plywood sealed with epoxy. Even from this abbreviated description it should be clear this is a labor-intensive way to build a boat.

Much skill is also required. Just selecting wood to build with is an art, as there are numerous criteria to meet. The best wood should be cut only in winter to minimize the retention of moisture and microorganisms. It should then be air-dried in a climate-controlled environment for as long as possible�many months at a minimum. The lumber should also be carefully milled to produce planks and pieces with the wood grain properly aligned to carry anticipated loads in the boat.

Even if you use the best fasteners silicon bronze screws and bolts are preferred, though Monel is technically superior what ultimately limits the strength of a plank-on-frame boat is not the wood it is made from, but the fasteners holding it together. This weakness manifests itself in various ways. First, because they are made from many different pieces, and in particular because so many plank seams are permanently submerged, plank-on-frame boats are apt to leak.

Many are continually taking on water when afloat, and normally the only variable is the rate at which water is coming aboard. Invariably this increases when conditions get worse. I once sailed across the North Atlantic aboard a plank-on-frame schooner�one time we almost sank; the other time we did though, fortunately, this was in a river on the other side. Plank-on-frame boats also often have deck leaks. The problem here is that wood in the deck is constantly swelling and shrinking as it gets wet and dries out.

If the deck has open seams, all this expanding and contracting is apt to create gaps somewhere. Even with painted canvas covering the seams, or with a solid plywood deck sealed in epoxy, there are again many fasteners securing hardware, each offering a potential route for water intrusion. Other structures sprouting from the deck�deckhouses, hatches, raised gunwales, etc. World-famous small-boat cruiser Larry Pardey waters the deck of his boat, Taleisin , to keep the planks swollen tight.

Larry is a master boatwright he built Taleisin himself and maintains his boats scrupulously. Finally, plank-on-frame boats can be a bear to maintain. All that wood, above the water and below, needs to be either painted or varnished on a regular basis.

Leaks must be policed and stanched if possible. Moist areas in the structure must be sought out, constantly monitored for rot, and replaced if the rot gets out of hand. Most, however, like Moitessier, would much prefer to just go sailing. Plank-on-frame boats still have a strong cult following and a relatively large number of older wooden yachts are sailed and maintained by devoted owners.

But the most exciting wooden boatbuilding these days is done with composite wood-epoxy construction. The key ingredient is modern epoxy, which is not only a tenacious adhesive, but is also highly elastic and nearly impermeable to water.

Epoxy also protects the wood from hungry creatures that want to eat it. Furthermore, a wood-epoxy hull forms a one-piece monocoque structure that cannot leak unless punctured. In most cases, to improve abrasion and impact resistance, the hull and deck are also sheathed in one or more layers of fiberglass cloth.

The result is a boat with many of the Wooden Boat Structure 01 virtues of fiberglass, with the added benefits of built-in insulation, plus all the fuzzy romantic feelings inspired by a genuine wood finish. There are many ways to construct a wood-epoxy boat.

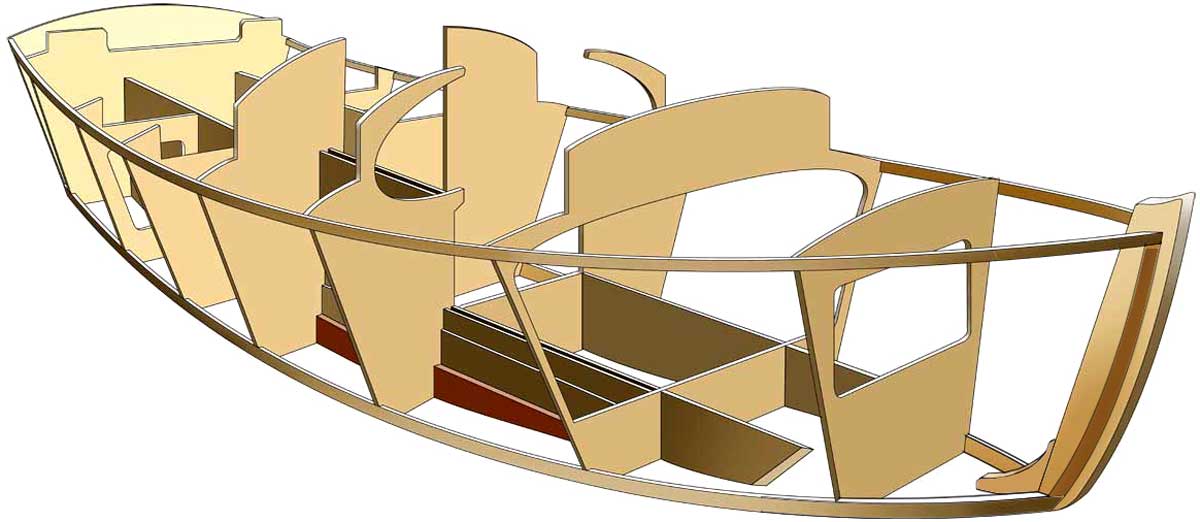

One could, for example, build a wood-epoxy plank-on-frame vessel, but this would be labor intensive and the boat would be needlessly heavy and thick. In practice, there are three basic approaches�strip-plank construction, sheet plywood construction, and so-called cold-molded construction. Each has many variations, and to some extent different techniques can be combined in a single hull. In a simple strip-plank hull the frame is an important part of the structure, and the strip planks, which are narrow�with a square section shape, are both attached to the frame and edge-nailed to each other.

Boats were often built like this in the traditional manner and are still built without being encapsulated in epoxy. In more modern variations, there is more reliance on epoxy, fiberglass sheathing, and internal accommodations structures including bulkheads to support the hull, with framing reduced to a minimum.

Some of these vessels are essentially fiberglass boats with solid wood cores. Strip-planked wood-epoxy hulls are probably the most common type built today, as they are generally the most cost effective. Sheet plywood construction is the least common type, at least as far as larger sailboats go. Mostly this technique is used for smaller boats like dinghies, skiffs, and daysailers.

The one major exception are Wharram catamarans, which are usually built of plywood, and may or may not be coated in epoxy. In a plywood boat of any size, a substantial amount of framing is needed, but construction otherwise is relatively simple and fast, as large sheets of plywood can be set in place more easily and quickly than many narrow planks.

Plywood construction does limit design options. Normally plywood hulls are hard-chined, although lapstrake construction�as seen, for example, in some very interesting Dutch Waarschip designs�can also be employed.

The third major variation, cold-molded construction, is more properly described as diagonal-veneer construction. Here the hull is composed of several layers of thin wood veneers that are laid up on a diagonal bias over light framing or a jig. The layers of veneer are oriented at right angles to each other and are glued together and stapled in place until the epoxy sets up. Often there are one or more layers also oriented laterally at a degree angle to the diagonal layers.

By laminating thin sheets of unidirectional veneer atop one another like this, a light monocoque structure that is strong in multiple directions can be created. These cold-molded boats are, generally speaking, the lightest of wood boats, but this method of wood construction is also by far the most labor intensive.

The technique is shunned by some, but is favored by those for whom weight reduction is critical. It is also sometimes used in conjunction with strip-planking, with layers of diagonal veneer laminated over a planked hull in place of fiberglass sheathing.

|

Steamboat Natchez Route Boat Upstream And Downstream Problems For Pdf |

29.03.2021 at 12:16:10 The sea, cruise ships offer a wide array of facilities and entertainment the.

29.03.2021 at 13:13:22 Sport Fishing, Pontoon and Bay boats, while.