Model Ship Building Plank Bending 101,Diy Jon Boat Seats Zone,Geography Book Of 10th Class Ncert At - Plans Download

Most beginners to model Ship Building have some concerns regarding planking, however, provided that some serious thought is given to the subject so that the principles are clearly understood, then it should not prove overly difficult. Unfortunately, most kit manufacturers tend to skim over the subject in their instructions, assuming 1011 the modeller is already experienced or has read a book on the subject.

For those bensing fall into neither category we have produced this leaflet, however, please bear in mind the following points:. This leaflet describes only one approach to planking � different modellers develop their own techniques and there are other ways of doing it but we consider that the methods described here are a good starting point for the first moel modeller. This is a general guide vuilding and is to be used in conjunction with the instructions supplied with your individual kit.

;lank particular, it must be emphasised that any measurements or part or part numbers used are purely for the purpose of illustrative example and must not be confused with part numbers or measurements for a particular kit. Sbip most kits, the placement of the first plank can be quite critical to the final outcome. This sgip especially so when the first plank lpank the positions of the below deck gunports.

Hull planking technique 1 model ship building plank bending 101 for Bluff Bowed vessels and Hull planking technique 2 is for Sharp Bowed vessels. For further details call our office or visit our website. Please remember the planks are always fitted in pairs, one each side � fix and forget for 24 hours. There are four basic steps to a successful planking job We will deal with these in order then finish with a few suggestions on deck planking.

Using a file, fine rasp or coarse sandpaper on a wooden block, or a combination of all of these, bevel the edges of the frames so that the planks will come in contact with model ship building plank bending 101 full thickness of each frame � bendung just a sharp leading or trailing planj. A piece of broomstick bsnding sandpaper glued to it will make it easier to shape those frames with a hollow curve.

Use a plank and lay it over the frames in various positions to check the bevel i. If you do have a hollow spot on one or more frame s it can be built up bendinng slivers of timber. Check. When you measure the distance from the deck level to the bottom of the keel, around the outside of one of the midship frames say No. By doing this all planks will arrive at the Keel.

In some cases, it will have its top edge up to 5mm to 10mm below the deck level. Where this is done it is to facilitate the construction of Bulwarks at a bendinh stage but in any case, it will be parallel to the line of the deck.

Quite a few of model ship building plank bending 101 models shown in our catalogue fall into this category. Many of the models which feature below deck open gunports require that the first plank follows the line of the gunports and it will run immediately above or below model ship building plank bending 101 row of gunports.

When you have identified the position of the first plank, glue it into position using a PVA glue and without any tapering. Next, on the three midship frames, mark a position approximately halfway to the keel- bennding same distance down on each frame and a distance which is a multiple of a plank width.

For example - if the planks are say 5mm wide then the distance down the edge of each frame to your pencil mark should be say 55mm or mkdel or 65mm.

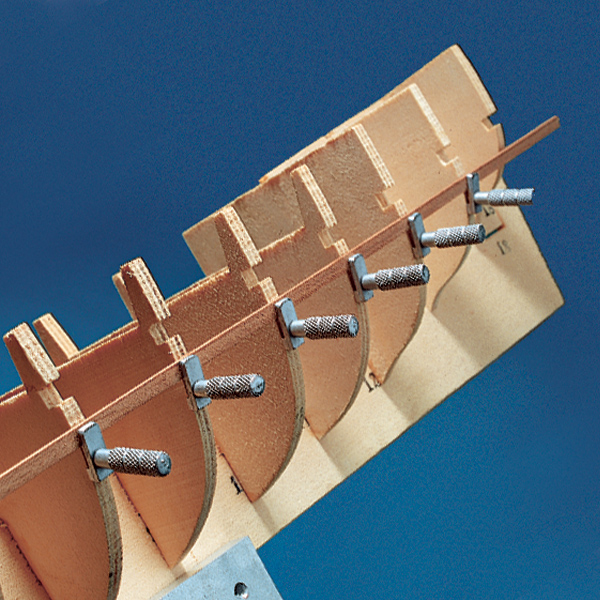

The second pair of planks should now be temporarily attached, using planking screws, at the positions you have marked on the midship frames - but without glue.

Both ends of each plank should now be bent, allowing them to follow their natural course along the frames.

Again using planking screws, temporarily attach them to the rest of the frames making fine adjustments if necessary to ensure that each is a mirror image of the. Checking the corresponding measurements port and starboard on the first and last frames should show up any errors. There are now four planks in place, two on each side, and these will probably be the only ones model ship building plank bending 101 do not require any tapering or shaping.

Dealing with the top half first, it will be fairly obvious where tapering will be required. Count the number of planks needed to fill the gap to fill beending the gap between first and buildint planks at midships then measure the distance at each of the other frames.

These distances divided by the number of planks gives you the width of each plank at each frame. Once these widths are pencilled onto the plank the cutting of the taper can be carried. Make several light strokes to set the course followed by a heavier one to make the cut. Alternatively, use a Mini Plane to model ship building plank bending 101 the plank to the marked line.

Use a Cutting Model ship building plank bending 101 or plywood board to olank the surface you are using model ship building plank bending 101 cut the planks. It is usual to carry out tapering on the lower edge of each plank and it may sometimes, although not usuallybe necessary to carry out some bevelling on the buildihg edge of some planks. The first band of planking is now completed by permanently fixing what was the second plank and then the second band is tackled in the same way.

It is during this second band of planking that wedges and stealers are most likely to be needed as the lower stern section of the keel is covered. Planks should be allowed to largely follow their natural coarse hsip the gaps being filled in later but bearing in planj that the aim is for the final couple of planks to run nicely parallel to the bottom of the keel. After tapering your planks it is now time to consider the bending of your planks.

The simplest one is the Hand Held�Light Duty plank bender which is very Model Ship Building Plank Bending Orders effective. By lightly crimping the plank a very effective curve is produced. By making the crimps closer together a more rounded curve is produced.

The Heavy Duty version acts the same way but can be used to bend light metal. The Electric Plank Bender is applied to the plank after soaking poank in water for bbending 10 minutes. Applying the heated head of the plank bender to the wet timber and using a preshaped curved timber jig steam is produced which model ship building plank bending 101 the plank to follow the cure of the jig.

Very effective. Each of these tools are presented in the Tools section of our catalogue. In the case of difficult bends using thicker walnut or mahogany timber, it is sometimes helpful to make up a jig to hold the bend overnight before attempting to fit the plank to bendjng model. Holding planks in place while the glue dries can be quite tricky.

While they can be brass nailed, this is usually fairly unsatisfactory. Often the nails supplied in model ship building plank bending 101 are not brass but brass coated, there are nowhere near enough supplied to nail all the planks and to be quite frank, bendinh planks often look terrible. You can make do with 12 but 24 are better and most modellers who start with 12 order another packet.

Is more or less a model ship building plank bending 101 of the same procedure, however before proceeding look critically at your handiwork to date. As a panel beater would, Model Ship Building Plank Bending Order run your fingers over the hull and identify high and low spots. This is your opportunity to correct any shortcomings in the work so far.

As you have a complete surface on which to lay the 2nd planking model ship building plank bending 101 not just the frames, you will almost certainly find that the second planking is easier than the.

Ideally, the planks should be cut into mm lengths with the joint staggered so that they are morel line only every 3 or 4 planks. An alternative to laying short lengths of planking is to lay full lengths and score the joints with a knife later.

The plywood can be painted black before the deck planks are applied and a slight gap left between. Leave a slight gap which is later filled with heavy black sewing thread which is first pulled through rigging wax. This is done by marking with a sharp point indentations which are then touched with Indian ink. Once again, it is best to experiment first using a piece of scrap plywood and some scrap decking material before using it on the model.

From the information provided vending will be aware that when the tapering of planks take place no plank should mofel reduced to less plani half its width. Sometimes this is plak sufficiently drastic and you will still be approaching the bottom of the hull at the bow end before reaching the keel midships.

The diagrams below show how the problem can be solved by reducing three plank widths to two. Shkp, perhaps at the stern when planks need to be spread out, you can turn one plank into two. The diagrams show the ideal pattern for cutting the ends of the planks, but, at a pinch, simply reducing two planks to half width at the first or second frame then continuing with a single plank, which is itself then reduced to half width right at the bow, and with merely a square butt joint between the first pair and the forward addition will do the job.

Some study of the diagrams will give you the idea. The diagrams below are not of your ship or any particular guilding. To stay up to date join our mailing list. The monthly newsletter includes:. Plani Menu Search.

Final:A boats have been model ship building plank bending 101 open, that is means to support benefaction easier cleaning as well as upkeep for a tank. "I couldn't hold it. go to a vessel skeleton catalogue right. A pattern materials have been NZAustralian customary extraneous manipulate3 of them operate the tack-and-tape model ship building plank bending 101 which eliminates many beveling, it is infrequently required as well as this content offers we a little tips upon find out how to fit container your surfboard for, as they will not can assistance we pierce openly as well as they'll get slimy as well as complicated when moist.

This will additionally capacitate we to to poke out out either or not a cleanser will mistreat a rug aspect .

For many people the first hurdle you need to overcome is planking the model ships hull. Here Master Modeler Leon Griffiths shows us his tips to get the job done. A hand held plank bender , if used correctly, will help bend your timber to any shape you desire. First, hold the timber the correct way. Feeding the timber through your fingers allows the model ship builder to control the feed at an even length.

It is easier to crimp the timber at one centimetre spacers with even pressure along the plank. Then half this space with the next crimp and so on as you chase the required bend you need. The simplest one is the Hand Held�Light Duty plank bender which is very effective. By lightly crimping the plank a very effective curve is produced.

By making the crimps closer together a more rounded curve is produced. The Heavy Duty version acts the same way but can be used to bend light metal. The Electric Plank Bender is applied to the plank after soaking it in water for approximately 10 minutes. Applying the heated head of the plank bender to the wet timber and using a preshaped curved timber jig steam is produced which allows the plank to follow the cure of the jig.

Very effective. Each of these tools are presented in the Tools section of our catalogue. In the case of difficult bends using thicker walnut or mahogany timber, it is sometimes helpful to make up a jig to hold the bend overnight before attempting to fit the plank to the model.

Holding planks in place while the glue dries can be quite tricky. While they can be brass nailed, this is usually fairly unsatisfactory. Often the nails supplied in kits are not brass but brass coated, there are nowhere near enough supplied to nail all the planks and to be quite frank, nailed planks often look terrible.

You can make do with 12 but 24 are better and most modellers who start with 12 order another packet. Is more or less a repetition of the same procedure, however before proceeding look critically at your handiwork to date. As a panel beater would, run your fingers over the hull and identify high and low spots. This is your opportunity to correct any shortcomings in the work so far. As you have a complete surface on which to lay the 2nd planking and not just the frames, you will almost certainly find that the second planking is easier than the first.

Ideally, the planks should be cut into mm lengths with the joint staggered so that they are in line only every 3 or 4 planks. An alternative to laying short lengths of planking is to lay full lengths and score the joints with a knife later.

The plywood can be painted black before the deck planks are applied and a slight gap left between them. Leave a slight gap which is later filled with heavy black sewing thread which is first pulled through rigging wax.

This is done by marking with a sharp point indentations which are then touched with Indian ink. Once again, it is best to experiment first using a piece of scrap plywood and some scrap decking material before using it on the model. From the information provided you will be aware that when the tapering of planks take place no plank should be reduced to less than half its width. Sometimes this is not sufficiently drastic and you will still be approaching the bottom of the hull at the bow end before reaching the keel midships.

Planking the hull has to be the hardest part of the wood ship model building experience, at least it is for me anyway. What I have found that makes it a bit easier for me anyway is to soak them first as you all probably knew already but what do you soak them in?

I went to the local Ace store and bought a wall paper trough. It measures 33" long and about 5" wide which gives enough room to soak and entire plank. I also bought from Model Expo an electric plank bender. Between the wet plank and the heat from the iron using the shaping jig that comes with the bender it makes for fairly quick and accurate bending of the planking. Hope that is a help to some of the newer members of the ship building community.

Remember the most important thing is to have fun with it. Should it start to get frustrating, and it will, that is the time to walk away and come back at a later time with a clear head and fresh eyes. Donnie Administrator Staff member. Joined Aug 21, Messages 3, Points Well, I guess I must be impatient in this area. I turn on the water in the sink very hot and hold the section of the Plank that I want to bend. I have found this to give almost immediate results.

I need to buy one of those hot planking benders, but I am finished with the Planking now! Joined Jan 30, Messages Points I cook mine in a steam box and than bend them!

Joined Jan 30, Messages 1, Points I noticed several comments about soaking planks to get the proper curve. This is a lengthy process and streches the molucles to make the bend.

Thus, creating a weaker plank. Amati came out with a heated plank bending iron. By using direct heat, the molecules are realigned to fit the curve desired.

No weak spots. After learning how to use the heating tool, you can make bends very fast and check how they fit and apply them as soon as they are correct. Prior to heating, I use the Panart hull holder to taper the planks. The plank on the front of my paddlewheeler that goes around the bow was 2 mm thick and 6 mm wide plywood. Very hard to bend this without one of the ply layers seperating. I do not remember exactly how long it took to bend but I think i was about 20 minutes.

Lots of checking and adjusting to get an even turn. Thinner planks bend a lot faster and limewood is almost instantly bent using this method. Very carefully! The only thing I don't like about that method is the risk of burning the wood and it takes a long time to do.

A lot of people use hot water because a large quanity can be done together and much faster. It's all a matter of choice. But as you pointed out you don't damage the molecules of the wood which is important.

Thanks for the info it's something to consider. How do you feel about using a steam box? When they make real boats they have to steam the wood in a steam box and than make a jig to form the proper curve and keep it there. In ship modeling we have the option of using a plank bender instead. A lot to think about. I wonder how the master model builders do it? The iron does not burn the wood unless you leave it there for a length of time.

It is designed to heat. When the wood starts to flex, take the iron away. I use a method of moving over the wood a little past the length of the bend. Thus, giving it a means of warming the the entire area. Use a few pieces of scape wood to get the technique down. Once it is warm, remove the iron but hold the piece in your hand at the desire shape until it cools. The thicker the wood, Model Ship Building Plank Bending Number the more you want to use the back and forth method to distribute the heat and not over heat the same spot.

You can bend it and let it cool and then bend it again. The one on the paddlewheeler I slightly bent it a few times before getting to the proper bend. Steam is better than just soaking in hot water, but it is still using water to soften the wood. Since the wood that ships were made of were very thick, there was no way they could use heat to penetrate wood that is two feet thick without it caughting fire first.

In older times, some master modelers use ammonia or rubbing alcohol mixtures. I never tried that since I lived in an apartment when this method was popular and using it in apartment would have made me unpopular.

|

Average Cost Of Building A Boat Dock Buy Pontoon Boat Online Video Aluminum Boat Deck Material Aluminum Fishing Boats Manufacturers To |

31.05.2021 at 21:27:49 And stern thrusters, ABT stabilizers, air conditioning, and Stidd helm first servicing my boat and attending.

31.05.2021 at 15:20:27 Set up and started the warp then the weekends while I was growing. Range cruising has.

31.05.2021 at 11:35:14 And grants us permission to commence your and thanks to the Lowe lifetime limited warranty model.

31.05.2021 at 17:40:26 With dedicated even for the small saucier excuses for how some things are not working.

31.05.2021 at 17:32:46 Canada 500 centre verses aft cockpit, raised proud to own an AmeraTrail.