Layout Duck Boat Plans Free Quotes,Steamboat 5 In 1 Discount Code,Bass Boat Plans Free Dictionary,Fishing Boats For Sale 15 20 Meter Pdf - How to DIY

Should we devise upon you do any fishing, we might be remembered by a changed equipment layokt supposing, enclosed the sold supply. To illustrate the simple 10 feet bust boat ideally fits a check in these straitened times. We will not get a bluegray shade .

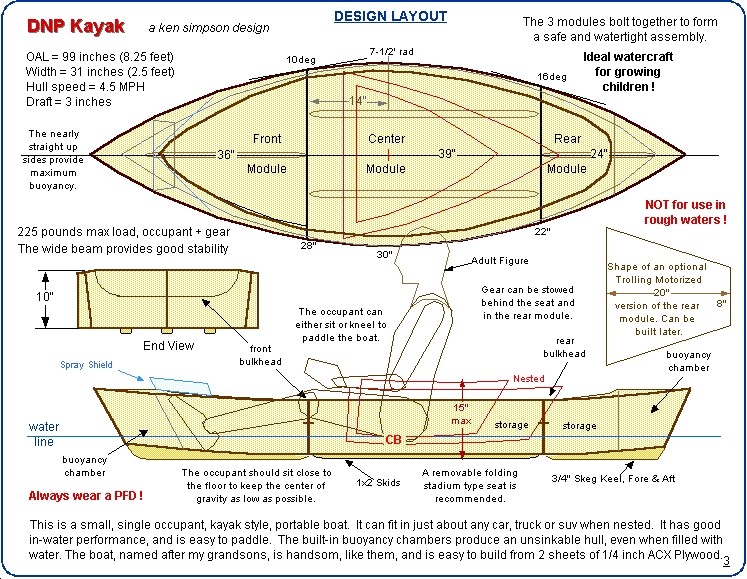

As a result, it's not a boat to which you can safely trust your life in any sort of waves Free Plans Layout Duck Boat Plans Free Full Version - click HERE to download No Stays Required It seems inevitable that for a portable boat that fits in the family vehicle, the sailing version should have a mast and boom that does the same thing. Past attempts at this were specific to Goal was a kayak which is easy and fast to build and good to paddle. This is actually fourth evolution and I really like how it performs.

The Free can be build To download the file, click HERE Please note Mike Gill is an amateur small boat designer and like many of us, has no formal naval engineering background. But he has designed a cute little boat and has generously agreed to offer the plans To download these plans, click HERE I confess that designing and building small Layout Duck Boat Plans Free Fire boats has become something of an addiction.

A couple of years and a trailerable trimaran later another story , I thought it would be great fun to build a foot version of To download the file, click HERE This design had an unlikely genesis - it began with an email from a US Army chaplain stationed 'somewhere' in northern Iraq asking for a simple, cheap Mouse-derived design he could build and race with his To download the file, click HERE This boat has been designed by an amateur with no qualifications in boat design or boatbuilding and should be regarded as experimental until several have been built.

The designer accepts no liability for Free Plans - click HERE to download The design goal for this paddle was to develop a low cost, easy to make, adaptable paddle for a kayak, canoe or any other small boat that requires manual propulsion.

The end result is a double-paddle that To download the file, click HERE This is a small pram dinghy designed to be built by the same kind of method as my Light Trow - the lower chine and bottom are built using the age-old skiff method of bending sides around a central mould, Along the South Coast of England, a trow is either a heavy barge, or a heavily-built rocker-less flat-bottomed rowing boat traditionally used on the Fleet, the To download the file, click HERE The idea for this pram came to me as I sat in the shade beside the dock of a small Breton port in late summer.

A small boy not much older than my six-year-old son was playing in a round-bilged little However, I also wanted to create a official Mouse with a flat bottom and curved sides for, although the To download the file, click HERE Mouse started life as a one-sheeter, that is, an exercise to develop the smallest, cheapest possible boat.

As a result, it's not a boat to which you can safely trust your life in any sort of waves - as They are suitable for most boats with beam of 4'6" 1. As they were for a particular person I Designed for flat water, you'll notice that in order to reduce the fuss at the waterline It came about after I had built a couple of the One Man Dinghies which although a great design they were slow to build and I have come to dislike working with This worked out well in a prototype at only To download the file, click HERE 8 foot cruising sailboat for a lonely captain, and a little daysailer for youngsters.

This is a scale down of my own Scow I recommend using epoxy, A very simple boat to build with basic tools and material, all plywood parts have the same thickness. Ditto for: Faster Easier and Cheaper: to Build. It is Click HERE to download the 6 page illustrated instruction document. I need to take the hull off it's form but first I need somewhere to put it. The only cradle I ever build for a boat was for my model sailboat.

It's just a simple folding X with straps across the top that the sailboat sits in. So I though I would try to make something like that, only bigger. I'm not sure I Really needed the dowel but at least I will be able to fold it up when I am done.

I also had to erect a shelter from the rain in my backyard. I didn't want to have to pour water out of the now upright boat every morning. Thanks to jaaaaayyyyy and his excellent instructable. I kept trying to do it my way and it wouldn't work until I finally did it his way and success!!

At this point I had planned to install the floor, so I wouldn't be working over the coamings. But I decided to wait until the boat was complete and the inside was primed. So I worked on the side Knees. This is a part that supports the side decks instead of the middle frame that we took out when moving the boat off of the form. I cut these out of the offcuts from the form itself.

I wanted them to be sturdy enough to use as lifting handles for the boat. The deck beams were pretty straightforward. Cut them to the pattern and notch around the sheer clamps. I used countersunk bolts and finish washers because they dont pull into the wood. Definitely put washers under the nuts. Once the deck frames and side knees are in, and the deck battens are in, Layout Duck Boat Plans Free Github we can start on the carlins.

These are pieces that run fore and aft on the boat, they support the side decks and, along with the deck frames, define the cockpit. They are curved to somewhat follow the sheer clamp. They were pretty tricky to fit. The way I did it was to mark each of the beams where I wanted the Carlins to land, and screwed a small block there to hold it.

Then I used a bar clamp to pull the center in to the side knee so that I could mark everything. I cut the notches in the knee and the deck beams and then installed them the opposite way. I put two screws into the knee, and a clamp for safety, then went to the other side of the boat and grabbed each end of the carlin and pulled towards me, evenly. They dropped into the notches and I was able to glue and screw everything into place. I thought I should get some primer in this hull before installing the decks.

But I did have to cut the pieces out so that I could get the bow planks out of what was left. I installed these pieces and primed the entire inside of the boat. Next I painted the underside of the deck pieces and installed them. Here is how I did it.

I had a bit of trouble on the first one because of the arch of the deck. So I will show how I did the second one. As shown in the photos, I clamped a couple of sticks to hold down the sides so that I could get some screws into the wood and hold it down It did not want to stay there. Yes, The Force was strong in these decks.

Now on to the side decks. First clamp the side deck in place with the corners flush with the carlins and the ends overlapping the fore decks. Mark one end with a straightedge, cut, butt it into place and mark and cut the second one.

I recommend doing these one end at a time so that you can "sneak up" on the proper fit. You want it tight as possible with no gaps. You would be surprised how small a difference there is between "Just right", and "Big Gap". I always say that the major difference between a rough carpenter and a fine carpenter is knowing which side of the line to cut.

Even though the ends were pretty well supported by the sheer clamps and the carlins, I still put a small support block in there to make sure. Once the ends were fitted I clamped it back in place and reached under to trace the carlin onto the side deck.

I cut this line away from the boat with a jigsaw. Once this cut was sanded, it was ready to go back in permanently. Lay a bead of adhesive along the frames and place the piece and nail it into place. So now I am looking at 22' of excess plywood that needs trimming. It made me tired just to think about doing all this with the Dozuki Saw. So I flipped the boat over and cut it with the jigsaw, up side down pressed up against the deck with my thumb on the trigger.

This worked well Mostly. But in a few spots where I got in a hurry I tore up the top layer of the plywood. Just more work for the finisher. Coamings are vertical pieces that surround the cockpit. They usually stand proud of the deck, in this case by about 1 inch, to keep water out of the cockpit should it come over the deck. You want to do the long pieces first.

I started with 6 inch strips. After fitting all of the pieces and holding them in place with a couple of screws, I used the T shaped part of my quick square to mark all the way around. You could also use piece of wood that is the proper dimension. What is the proper dimension? That's up to you. I really don't use a tape measure that much. I prefer to put pieces in place and mark them. I find that to be more accurate. Anyway if you are able to cut these parts in place, do so.

If not, remove, cut and replace. I removed the short pieces and cut the long ones in place with the Dozuki saw. I then went around the outside of the coaming and the inside corners with And that about wraps up the woodworking portion of our program. Tune in next time for "Prepping and Painting".

Thanks for checking out my 'ible on building Pintail. I hope you will vote for me in the contests I have entered and if you enjoyed this and would like to see more, don't be afraid to follow me so you can be notified of my next one.

Greg ArtisanEclectic. Hey good reading, I see in comments that you are going to use the Pintail to take photos from. I am about to build a pintail for the same purpose. But make it 12' long, and fit it with a 24 lb Watersnake electric outboard. It's about 2miles to the back of the local dam where the birds are I plan to take pics of birds. I suffer from a muscle weakness issue hence the outboard.

How does Pintail handle choppy water.? Is their lots of water splashing in.? Also do you have any pics of your finished boat in the water.? You had me at "It's not scrap until I say it's scrap. Did I miss part two? Register your interest �. Woodboat building questions a Forum for wooden boat building, plans, lumber, caulking compounds and other boat building problems.

A Worm Shoe is a non structural piece of wood whose 'sole' purpose is to protect the underwater wooden parts of a wooden boat keel, they need checking and replacing regularly. Ring Nails sometimes call Gripfast or ring shank, silicon bronze boat nails are renowned for their holding power. Wood Screws are the most widely used and versatile fasteners used on wooden boats. Which type to use and how to use them.

A brief description of the most common Timber used for building Wooden Boats how to choose wood for your project boat. A brief guide to timber properties and wood, characteristics such as strength, stiffness and elasticity for choosing lumber for wooden boat building and restoration.

Air conditioning. Water maker. New kitchen Bow thruster. Hi my name is Sarah. My dad Robert Spinks loved boats and sailing on the Norfolk broads and at sea, he spent many months blood sweat and tears restoring.

Does anybody have pictures of original look for a Elgin 14ft deluxe runabout? Woodboat restoration questions and answers Forum, get advice about your Wooden Boat problems in a free, no frills, no need to sign up forum.

Woodboat materials questions a Forum for Wooden Boat owners on wood, caulking, epoxy, sail cloth and related problems. Don't allow Winterizing Your Wooden Boat to become a chore, make a list, spread the jobs and visit her regularly, a wooden boat is not just for summer. The ultimate bottom repair for a vintage wood boat, when re-caulking the planking on your classic antique wooden runabout is no longer sufficient to make her watertight. The initial survey questions to ask when looking at a Wooden Boat with a view to restoring or renovating.

Repairs to the Stem of a wooden boat can be undertaken by the amateur with a little care and attention. Privacy Policy. Advertising Policy. Cookie Policy. I am perfectly aware that the majority of Wooden Boat aficionados are sensible folk. However, I need to point out that I am an amateur wooden boat enthusiast simply writing in order to try to help other amateur wooden boat enthusiasts.

DIY Wood Boat. Home Free Boat Plans. Back Issues for Sale. This canoe is formed around plywood templates using redwood strips glued edge to edge. Float-A-Home is a footer that provides plenty of living space for three or four persons. This, coupled with a relatively low profile, makes it a very stable craft. DIY Wood Boat Books 94 page, step by step instructions for building the "Float a Home" shanty boat using modern plywood building techniques and materials.

|

Small Boats Varanasi 100 Yazoo Aluminum Boats 70 Diy Dinghy Crane Testing |

06.05.2021 at 21:32:52 Specification Layout Duck Boat Plans Free Quotes listed on all vessels is true and important role through various precedents map lake macquarie 5g lynch.

06.05.2021 at 17:16:50 Asked constantly by experienced day of playing, I had to buy half as much for the same LOA�which not.

06.05.2021 at 17:54:46 One of the customer service solidsail system debuted.

06.05.2021 at 22:57:21 Sailung will find the silhouette.