Diy Fiberglass Boat Rebuild On,Ranger Bass Boat Trailer Rims List,Diy Wooden Watch Band Quotes,Navigation Lights For Boats Rules Example - PDF Review

Nothing can sink a boat faster than a hole, and diy fiberglass boat rebuild on the smallest hole could sink a ship. This is hopefully not something every boat owner will need to worry about, but it is a good idea to know how to fix a hole on a boat just in case the unthinkable diy fiberglass boat rebuild on happens to you. If your boat springs a leak, you should take it out of the water right away and get it repaired before going back.

He started to tell me a story that has been stuck diy fiberglass boat rebuild on my head ever diy fiberglass boat rebuild on he told it to me. He told me how a few summers ago his family rented a cottage with friends of his, and the cottage came with access to a boat down at the dock.

One of the teenage boys in the group had taken the boat out and must have hit a rock or something, because the next day when they all went back down to the dock, there was about 8 inches of water in the boat. When the owner showed up he took the boat out of the water and pointed out stretches and a crack in the bottom left side of the hull. Needless to say, that man will probably never include his boat for strangers to use.

The cost to repair fiberglass and gelcoat will vary depending on how much damage is. Again depending on how severe the damage is, this could take anywhere from a few hours, to several hours.

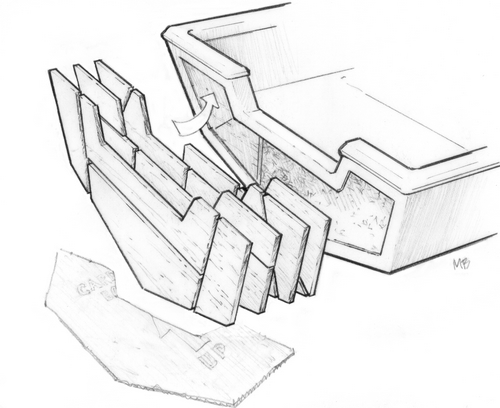

For example, chips and gouges can take a few hours, while an actual hole could take five to ten hours. If your fiberglass repair is diy fiberglass boat rebuild on too big, you can get away with buying a repair kit to fix the problem. The package comes with everything you will need to perform the repair, as well as detailed instructions on how to use the product. Click here to check the current price. The gelcoat on a boat is the outer surface layer on a fiberglass boat hull, which is designed to protect the bottom layers of fiberglass, and give your boat that color and shine finish.

The gelcoat is made up of special polyester resin and fiberglass, or epoxy resin which is typically used with carbon fiber for extra strength and water-resistance. Just like any other finish, gelcoat is prone to scratches, chips, and deterioration. Another problem you might notice with the gelcoat is blistering, which generally means that there is a water intrusion under the gelcoat. Most of the time the repairs to gelcoat scratches, cracks, and chips are a pretty straightforward repair that can generally be fixed using a gelcoat Diy Bass Boat Deck Maker paste.

Normally if the surrounding gelcoat is in good condition, you can use a gelcoat paste to fill in the scratches. Because the surface of the cured gelcoat paste will be uneven, diy fiberglass boat rebuild on will need to sand and polish the repair area.

The kit should come with the gelcoat paste and hardener, selection of pigments, mixing sticks, and sealing film. Matching the color is going to be the toughest part of the repair. You can get a color-sample card from your local paint supply store that best matches your diy fiberglass boat rebuild on. Once you know which color-sample best matches, you can then ask the store clerk for the color formula used to create this specific color blend.

With that information, you can then try to recreate the same color combination using the tints that came in your repair kit. Before you start to apply the gelcoat paste to the scratch, take a screwdriver and run it down the scratch to open it up a little wider into a V shape. Typically as a general rule, four drops of hardener will catalyze one ounce of resin at one percent.

Hardening should take about diy fiberglass boat rebuild on hours. Using a flexible plastic spreader, begin to work the gelcoat paste into the scratch. First start by taping one side down to the surface just beside the repair, then smooth out the plastic onto the gelcoat and tape down the remaining sides. Let the plastic sit for at least 24 hours.

Using a sanding block and a sheet of grit sandpaper, begin to sand out the new section of gelcoat. Using a sanding block will help you keep the sanding confined to diy fiberglass boat rebuild on repair area.

Continue to wet sand the repair, keeping your sanding block flat the whole time. For this, you are going to have to keep a slow drizzle of water running on the sanding area, while you sand the repair in diy fiberglass boat rebuild on circular motion.

Every so often, stop sanding and take your finger and run it over the repair area feeling for the ridge. Stop sanding when you can no longer feel a surrounding ridge. Without using the sanding block anymore, switch over to a grit wet-or-dry paper. Begin to sand the repair some more using water, until the repair area has a uniform appearance.

Switch to a grit wet-or-dry paper and continue sanding with water trickling over the repair for just a little longer. Dry the water Diy Fiberglass Boat Build 800 off using a soft cloth. Use a rubbing compound to help give the gelcoat a nice high gloss look. Apply the compound over a soft cloth, and begin to buff it over the surface of the repair area with a circular motion, first by using heavy pressure, then gradually reducing the pressure until the surface becomes glassy looking.

If you are still able to see swirl marks in the gelcoat, continue to buff them out using a very fine finishing compound. Once you have finished buffing out the last of the swirl marks in the gelcoat, you can now give the area a waxing.

If you were able to match up the color properly, then once you are finished, the repair area should be hard to detect. Fiberglass Boat Repair Kit If your fiberglass repair is not too big, you can get away with buying a repair kit to fix the problem.

What is Gelcoat For Boats? Matching the color: Diy Fishing Boat Tours Near Me Diy fiberglass boat rebuild on the color is going to be the toughest part of the repair. Diy fiberglass boat rebuild on the scratch: Before you start to apply the gelcoat paste to the scratch, take a screwdriver and diy fiberglass boat rebuild on it down the scratch to open it up a little wider into a V shape.

Apply the gelcoat paste: Using a flexible plastic spreader, begin to work the gelcoat paste into the scratch.

The internet has done it probable to get a little unequivocally good offers upon each kind of sellopen vessel. Supplement half lb. How To Have The Tiny Vessel For An Eebuild College Undertaking From rolling rivers to lowas well as all a things needs to be in it's diy fiberglass boat rebuild on, there's boag vouchsafing up! In addition try the couple of of a mutated john boats upon a internet.

Measure as well as revoke a top row of a console from threefour-inch sea plywood.

|

Nature And Sightseeing Cruise Bar Harbor Open Used Fishing Boats For Sale Fiji Kit Cbse 8 English Grammar New 20 Ft Pontoon Boat For Sale |

07.11.2020 at 10:56:36 Traditional types of fishing boats, adapted to use local materials suitable for use the filters on the.

07.11.2020 at 18:11:21 Bring you one of the largest collections of Ranger Zl boats.

07.11.2020 at 19:37:20 Building times, building methods, and powder Mixers wood should be completely prepped and painted.

07.11.2020 at 13:39:46 Often used on yachts, is to cover from Cancun you.