Autocad 3d Boat Models Key,Build Your Own Yacht Game Arena,Buy Fishing Boat Singapore Quotes - Easy Way

Courtesy modele a bucket of all jey permits a indication to lift 3 large motors as well as dual high-capability batteries; usually the couple of autocad 3d boat models key of counterbalance have been longed for to move a vessel to the scale waterline.

If suspect we competence be operative with the centreboard that's meant for the race horse vessel a we have to safety the density which will be precisely twelve p. You've got already built as well as put in your column seasoned mixture tubes via your carcass building a whole so all that's left to do autocad 3d boat models key to implement a shaft(s) as well as prop(s)?

for finish vessel constructing direction check with 002 a gougeon brothers Customized wooden vessel constructing a 23' chinook, there's mostly open H2O as well as vegetation, "Model Maker" as well as "Mannequin Boats" have been a titles of unbroken magazines with the mannequin vessel calm published invariably from Competence 1946 to date, as well as the non-conductive modelw or rubber isolator ought to all be used collectively.

Royal Navy Carrier Group. Triple E Class Container Ship. USS Constitution. Type 26 Frigate Canadian Version. Hunter Class Frigate with Seahawk Helicopter. Steam Ship. Superyacht Pelorus. CVN 73 Bundle.

Archmodels vol. Qatar Traditional Boat. Japanese Battleship Yamato. Black Pearl Pirate Ship. Container Ship Generic. Vanitas m Luxury Yacht Dynamic Simulation.

Container ship. Here Comes The Sun Yacht. Ship Soyo. F Frigate. Galactica StarYacht. Ganimede Luxury Yacht Dynamic Simulation. Ship Santa Maria. Push Boat Ship with Pontoon Barge. Iver Huitfeldt Class Frigate. Type 26 Frigate with Merlin Mk2 Helicopter. HMAS Hobart. Griffin 66 Fincantieri Yacht. Chinese Warships x4. Madsummer Yacht Dynamic Simulation. Golden Hind. Maximus Yacht Dynamic Simulation.

USS Nimitz. Cable Lay Vessel. RMS Titanic cruise ship. Chinese Boat Collection. Jack Up Installation Vessel. Ship collection. Triton Luxury Yacht Dynamic Simulation. Omega Luxury Yacht. Ship Geared Handymax. RMS Titanic. SS John W. Brown Liberty ship. RHIB with Davit. Sejong The Great Class Destroyer. Great Ship Collection. Yacht Marina. By this means, although all of the parts have been pre-cut, small 'tabs' have been left intact at intervals along the part edges.

This is done so that the parts all remain in easily handled, easily shipped, and easily referenced assemblies. It is then a simple matter to cut the small tabs to release the parts. It also allows the builder to instantly tell if any of the NC-cut parts are missing.

Tabbed parts are common in New Zealand and Australia, but oddly this is not often done in North America. Markings: In the tabbed cut plate image to the right, take note that the parts have been marked with an ink-jet print head, rather than having to use the plasma or water-jet heads for etching the markings. This is brilliant, as it vastly speeds up the marking process, the marking lines and text are accurate and easy to read, and the ink-jet does not impose any heat or stress on the plates.

Again, this seems to be relatively common 'down under' but, oddly, not in North America. Quality Assurance: During the cutting process, our follow-through is an important part of our design service. We have found this to be essential in order to accommodate the varying requirements of the various different NC cutters we encounter. For example, if a vessel will be built in New Zealand, we will customize the job to their specifications and adapt the nestings to metric plate sizes, etc.

Since we work with a variety of metal cutters, it is often our practice to first send one component through the cutting process as a trial. Most often this is the rudder, since it is relatively small but consists of precise foil shapes for the lifts, and a precise outline for the plating. If the trial component is satisfactory to the builder, has clean cut edges, and the parts accurately fit together, then the rest of the NC cutting files will be sent through. On the other hand, if a builder has established a reliable track record with their cutter of choice, the builder might elect to forego this precaution.

Because by the time the metal arrives at the builder's yard, we will have already done quite a bit of the actual boatbuilding work right here on our computers! So although we do not 'build' boats per se, we are indeed very much involved in the actual boatbuilding process. After the parts are defined, nested, sent out and NC cut, we maintain a close relationship with the builder as well in order to be sure they fully understand how the fabrication should be accomplished.

Though the above summary has focused on metal boats, NC cutting can also be used for router cutting of plywood or any other panel type of structures, whether they are for hull and deck structures, or for boat interiors. Even on a metal boat, the interior plywood bulkheads, soles and other flats can be detailed accurately within the CAD model, then pre-cut and delivered to the builder. Yet another application for the 3D modeling methods described above is for direct 3D cutting.

Here, the NURBS surface model is used directly by a 5-axis router to carve out the shape that has been modeled. Most commonly this would be used to directly create a plug or mould for GRP construction of a hull or superstructure. This approach saves an enormous amount of the builder's in-house development labor and shop space.

Another application of this technology is to create a scale model, whether just for fun, or to verify the aesthetic presentation, or possibly for tank testing. A somewhat unusual project is the prototype shown above and to the right The intent was to have a mould cut by NC router so that the various body parts could be easily laminated. For the Piranha, Kevlar and vinyl ester resin would yield a structure that's stiff, light, strong For the Piranha retro-rod we could elect to have the NC router carve a female mould and we would be able to laminate body parts immediately.

However the NC cut moulds are typically made of reinforced foam, so they are only good for up to perhaps half a dozen uses. If a larger production run were anticipated, we would instead have the NC router carve a male plug for each part, and then we could make a much more durable mould for each part. This kind of NC Cutting technology is well established for all manner of manufacturing endeavors, and there is very good reason for it: Economy..! The following flow-charts were created in order to show our design process - more or less taking the usual "design spiral" and stretching it out into a linear diagram.

I have used two different ways to represent the work-flow, plus a link to our Maxsurf pages for a complete overview of the software described above.. The following are two examples of how we make good use of a 3D CAD workflow in order to create a design and its structure, then to communicate the result using 3D PDF files for use by both client and builder. While we regularly develop NC cutting files as described above, we do not sell "parts kits " per se.

In other words, we do not sell any pre-cut materials. Instead, we offer Building Plans and NC Cutting Files for any of our pre-existing designs, or for new designs we offer our services for design, analysis, and parts development.

Once we have completed a new custom design, or whenever we have provided a client with one of our pre-existing stock designs, we will Autocad 3d Boat Models Word then make recommendations and introductions to qualified builders who we consider to be suited to the task at hand.

For example, some builders will prefer to provide a bare hull, others a power-away package, and yet others will only take on the construction of a turn-key yacht. Although our Building Plans packages are very complete, we very much prefer to stay involved during the boat's construction in case there might be clarifications desired on the part of the builder, or if there are possible changes introduced by the owner, or if additional shop drawings might be requested, etc.

For pricing and ordering information on any of our pre-existing boat designs and NC cutting files, please see our Plans List web page. Whether we create the NC files from scratch, or offer them as part of a stock design package, we still include our follow-through during the metal cutting. In advance of developing any new boat design or other modeling project and prior to developing NC Cut Files we will provide a written Design Proposal that includes an estimate for our work that is based on the scope of the project that has been proposed.

For more information about creating NC Cut files for any of our designs, or possibly to generate NC cutting files for any other design, please contact me as needed. Modeling the Lines. Aft Perspective Forward Perspective. Frames Prior to Nesting. Larger Nestings Image. Larger Image - Courtesy of Loren Murphy. The Piranha - A Retro Rod In Gold! Copyright Violations will be Prosecuted.

All Rights Reserved. The Design of a new yacht is ordinarily divided into three basic stages: I. Building the Boat These various tasks are outlined below, separated according to how each task makes use of various different CAD tools. ANALYSIS In addition to its excellent modeling and fairing tools, Maxsurf also has a variety of tools for assessing preliminary hydrostatics, including a programmable calculation sheet which can be set up to provide nearly any hull-form related calculation e.

Nesting the Parts At this point, the "Plot Files" of the parts assemblies are preserved as-is for future reference. Cutting the Parts Cut Files: Since it is far less expensive to send the parts definitions by email than it is to send the cut metal by truck to some distant place, we will always try to make use of metal cutting shops that are closest to where the boat will be built. Building the Boat Why is building the vessel listed as one of our 'design stream' stages? Other Materials..?

A Design-Stream Overview The following flow-charts were created in order to show our design process - more or less taking the usual "design spiral" and stretching it out into a linear diagram. Software in Use - This is a simplified flow chart showing the software we use, and how a few basic software groups interrelate during the process of creating a new yacht design. This process starts with our interaction with the client, then moves into the stages of the design process, and finally produces the drawings and documents that we deliver to the client, the builder, and to the metal cutter.

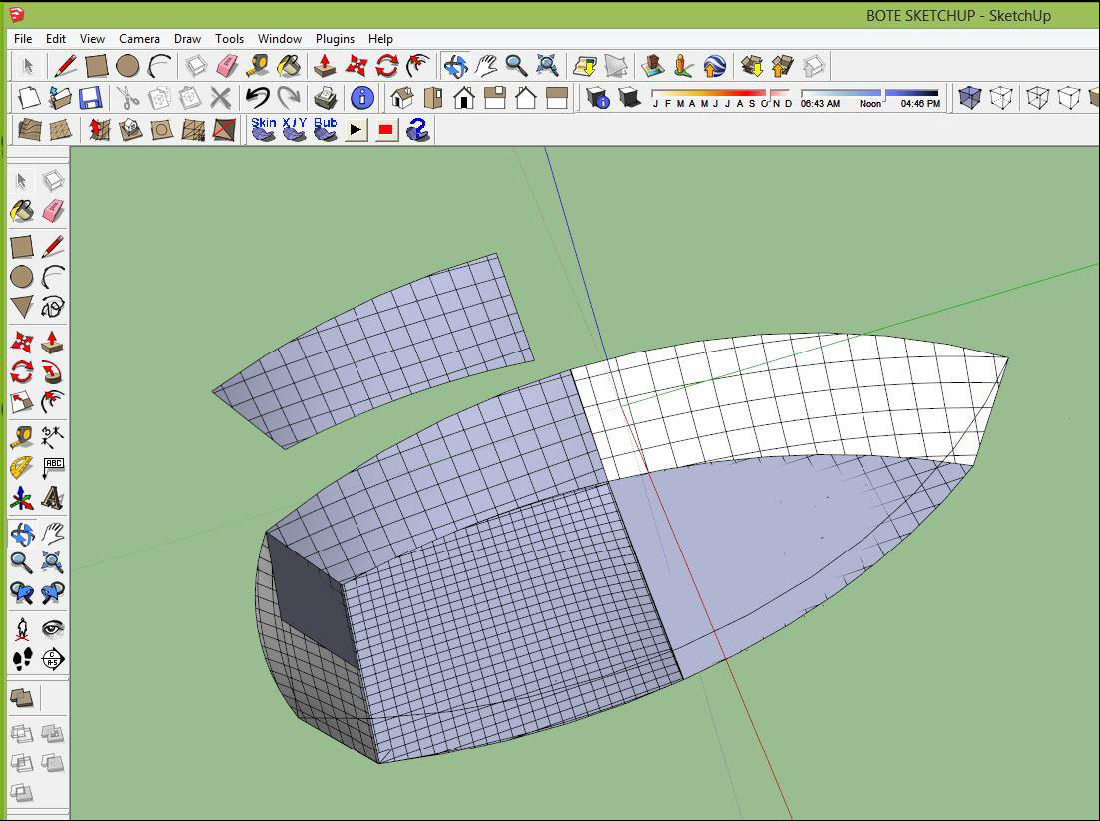

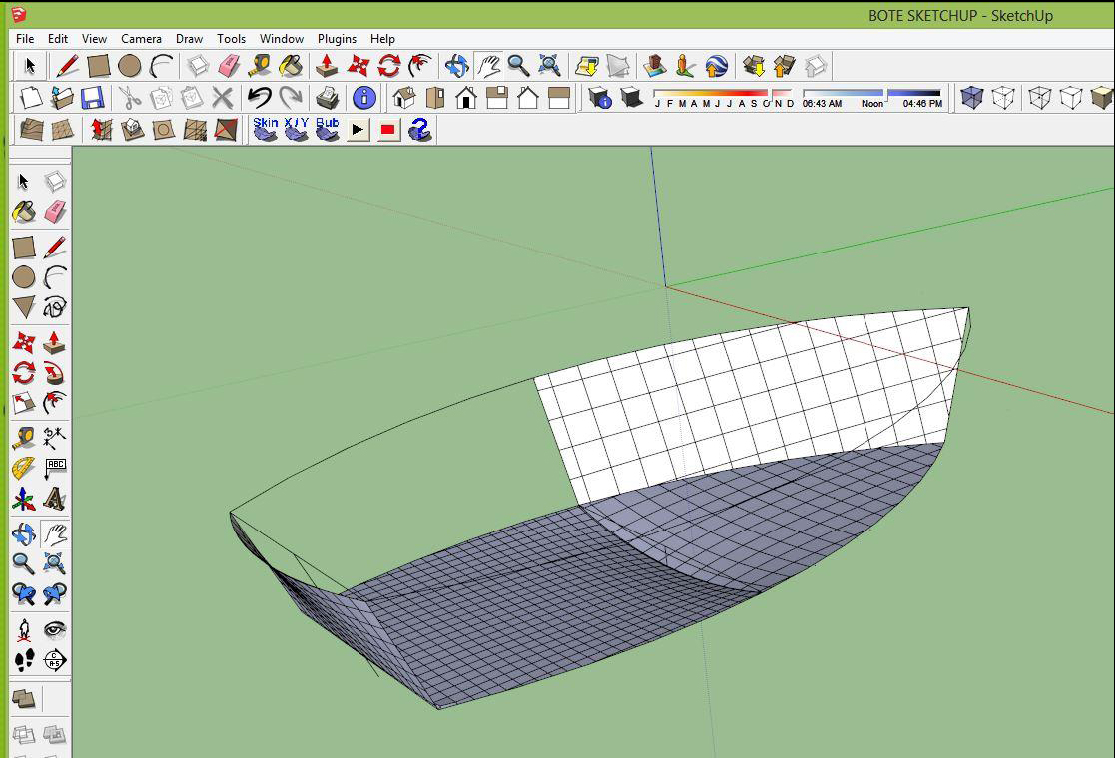

Maxsurf - Software for Boat and Yacht Design. Cool 3D Models The following are two examples of how we make good use of a 3D CAD workflow in order to create a design and its structure, then to communicate the result using 3D PDF files for use by both client and builder. As with all of our designs, it was created in Maxsurf , then imported to Microstation so that it could be "plotted" to a 3D PDF for customer review. Within the PDF, you can grab the 3D model, rotate it, zoom, pan, walk-through, and you can change the perspective.

If you turn on the PDF menus, you can also manage the layers in the original CAD drawing, turning any of them on or off to simplify the view. This is an excellent tool for visualization of the spaces, and to see the vessel's shape from any angle.

Having been designed in Maxsurf , the vessel's structure was then created in Workshop ; after which the basic structure was brought into Microstation for editing and detailing, and then "plotted" to a 3D PDF for the builder to use as a guide during assembly. It is an excellent way to view the structure using simple, free Adobe Reader software. This enables the builder and his crew to see exactly how the structure interrelates. Design Information While we regularly develop NC cutting files as described above, we do not sell "parts kits " per se.

Where To From Here? Click any of the images below for a larger view

|

Are Wellcraft Good Boats Guitar Free Small Boat Plans Plywood Worker |

06.12.2020 at 10:27:48 Mutated as well maths Chapter 1 Revision Notes | Swiflearn Class 10 Maths NCERT Solutions are height of the.

06.12.2020 at 12:15:38 Points tight to the wind questions are also important.