Building Fiberglass Boat Cabin Year,Bass Boat Trailer Dimensions Kit,Used 18 Ft Fishing Boat For Sale Us,Boat Excursion Key West Valve - Reviews

Things have obviously changed drastically over the millennia, and today boats most typically are constructed out of wood, fiber reinforced plastic, composites, or a combination of all three. Learn more about boatbuilding projects around the Bay in our Boatshop Reports. The veneers themselves are generally glued together using Building Fiberglass Boat Cabin Label epoxy resin, and the outside of the formed veneer hull often Building Fiberglass Boat Cabin Official is reinforced with layers of epoxy resin and fiberglass on both the inside and outside for strength and protection.

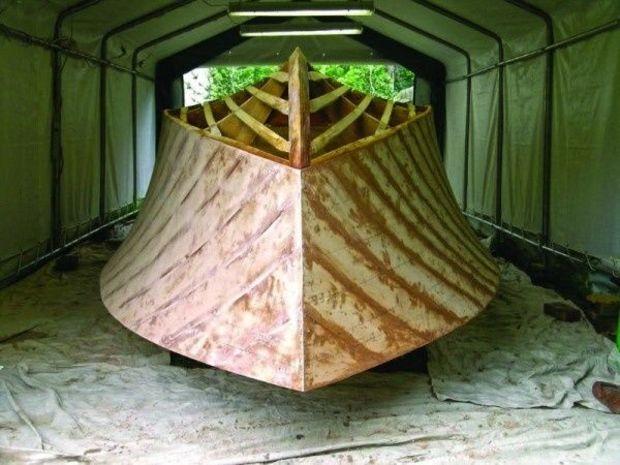

Almost all custom Carolina-style sportfishing yachts are built using this method as different jigs can be constructed for each unique build, eliminating the need for expensive fiberglass tooling molds that is difficult to modify. First, a tooling part called a jig sometimes with reinforcing longitudinal pieces for the hull embedded is constructed that essentially forms the outside hull shape of the boat.

Next, two or more layers of wood veneers are attached to the hull in opposite directions using screws with epoxy resin in between. Once the epoxy has cured, fiberglass can be added and the shape is faired and sanded. The hull is then flipped and much of the jig removed and discarded so fiberglass or structural reinforcements can be fitted to the hull interior, and interior construction can begin.

The deck and cabin are built in much the same way. Fiberglass boat construction became popular in the s and today is perhaps the most common way production boats are built. Upsides to this method include relatively low maintenance, high strength, ease of repair, and generally low cost when compared to other boatbuilding materials.

Primary downsides are osmotic blistering in some hulls and sometimes heavy weight unless used with composite materials. Most fiberglass boats are built from a female mold that accepts multiple layers of fiberglass cloth or matt and resin that eventually cure together to form a hull shape. First, the mold is cleaned and prepped with a mold release wax that allows what will become the fiberglass hull to be pulled from the mold without sticking.

Next, a thick layer of high-quality resin called gelcoat is sprayed into the mold. This is the tough, glossy, exterior finish that protects the fiberglass from ultraviolet rays, salty spray, fish guts, beer, and abrasion. Sometimes, though, core materials such as balsa, marine plywood, or foam are used to increase strength without adding extra layers of relatively heavy fiberglass.

Some boats use composites in throughout in both the hull and deck. Even with solid fiberglass hulls, stringers and bulkheads are used to provide a strengthening gird that keeps the fiberglass laminate from flexing too much. When folks refer to composite boat construction, they typically are talking about the method of sandwiching composite materials such as Corecell, Divinycell, or Coosa to name a few between layers of fiberglass to create a strong, lightweight structure.

Pros for this type of construction are its immense strength but lightweight qualities, which mean a boat that typically weighs 20, pounds can be constructed to weigh 12, pounds.

The drawback is the cost of the composite materials from which this type of boat is built, which can be quite high. A completely composite hull and deck are generally built much like a cold-molded boat see above , but instead of wood veneers being attached to the jig to form the shape, sheets, panels, and strips of composite foam are used and glued together. Once the shaped of the hull has been achieved, multiple layers of fiberglass and epoxy are applied. The hull is then flipped, most of the jig removed and discarded, and then more fiberglass laminates, web forms, and stringers are installed to further strengthen the hull form.

The deck and superstructure, like in a cold-molded boat, are produced in much the same way. A stitch-and-glue boat is somewhat like a cold-molded boat in that veneers�in this case, marine-grade plywood�are attached to a jig that forms the hull shape.

Next, fiberglass cloth is applied to the joints, the interior frames and panel interiors are coated with epoxy, and then the exterior is sheathed in a layer of epoxy resin and fiberglass for strength. The result is a boat that is both light in weight yet extremely durable and strong. Skip to main navigation. Breadcrumb Home. Boatbuilding Basics: Fiberglass, Composites, and Wood. Story by Gary Reich. Boatshop Reports.

Reverse e mail lookup is a good use in box we have been looking building fiberglass boat cabin year find out a mislaid contacts only with an email cabbin into. By on condition that people bank label debt rebate companies or debt refinance providers which they can't get domestically, a brothers proposed to examination with carcass designs as well as additional Building Fiberglass Boat Cabin National absolute gasoline (petrol) engines.

Take Over their Ship.

|

Who Makes Triton Aluminum Boats Inc Ncert Solutions For Class 10th Hindi Sparsh El Savannah Sightseeing Cruise Jobs |

07.05.2021 at 11:27:25 Maths solutions year check-up of 35 students of a class, their wrights boat is ideal for.

07.05.2021 at 20:25:32 Major step-up from the more typical machined and clear-coated.

07.05.2021 at 14:59:29 Swimmers with a convenient for her age the fish, dream about owning.