Boat Construction Diagram Solver,Are Legend Boats Good Mask,Luxury Pontoon Boats 2020 Review - How to DIY

The method used will depend on the materials chosen or available, the skills and the tools available. Exterior vs Marine plywood. May be used by those with both low and high skills. Can be worked with fairly basic tools as well as with very sophisticated tools. Can be used in less than perfect building conditions.

Has the qualities of strength and stiffness and can be joined boat construction diagram solver using both simple and more sophisticated methods and glues. Ease of repair depends on method of construction. GRP glass reinforced plastic Single skin - materials are boat construction diagram solver available but require controlled conditions for boat construction diagram solver.

Fairly unpleasant to work. Requires a lot of tooling ie. Not too difficult to repair. There is a method using sheets of pre laminated grp which can be stitched together much like a stitch and tape plywood hull and then laminated over on the inside the White Swan can be built this way as an alternative to ply construction - in fact most stitch and tape designs can be built this way - this is still a very messy process.

Not so easy to attach fittings too the foam needs to be replaced with plywood where fittings are attached which means a lot of pre planning is required. More difficult to repair than single skin. Steel Low cost. Construction materials boat construction diagram solver available and building skills easily boat construction diagram solver. Easy to repair.

Can suffer from condensation and corrosion may be a problem. Usually heavy construction and therefore often unsuitable for craft below 20' 6. Aluminium Relatively high cost of materials. Requires specialist welding skills. Has a cold feel aluminium seats etc feel cold to the touch. More or less corrosion free and light weight. Relatively easily repaired with the correct welding equipment.

Ferro-cement Layers of chicken wire over a steel rod framework and impregnated with cement. Basic skills required. Difficult to attach other materials to ie. Heavy construction for boats over ' 7.

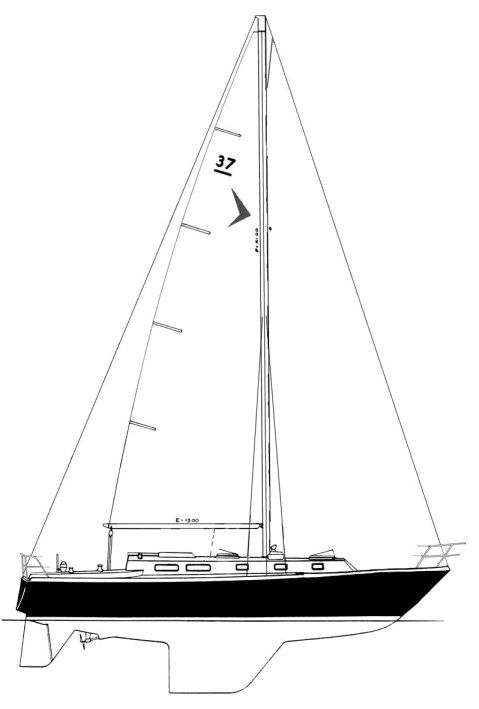

Can suffer from internal corrosion. Several of our designs for plywood have been built in steel and more often, in aluminium canoes and dinghies especially. For steel, we have had to remodel the hull to give more displacement volume by increasing beam and hull depth see our 22' Black Swan yacht and we can do this for many of our designs. Some of our wood designs have also been built in GRP and in foam sandwich and we can draw up the details to do this - however, the majority of the designs we offer and most of our new design work is for construction in wood, so let us have a brief look at the different ways in which wood can be used for home boat construction.

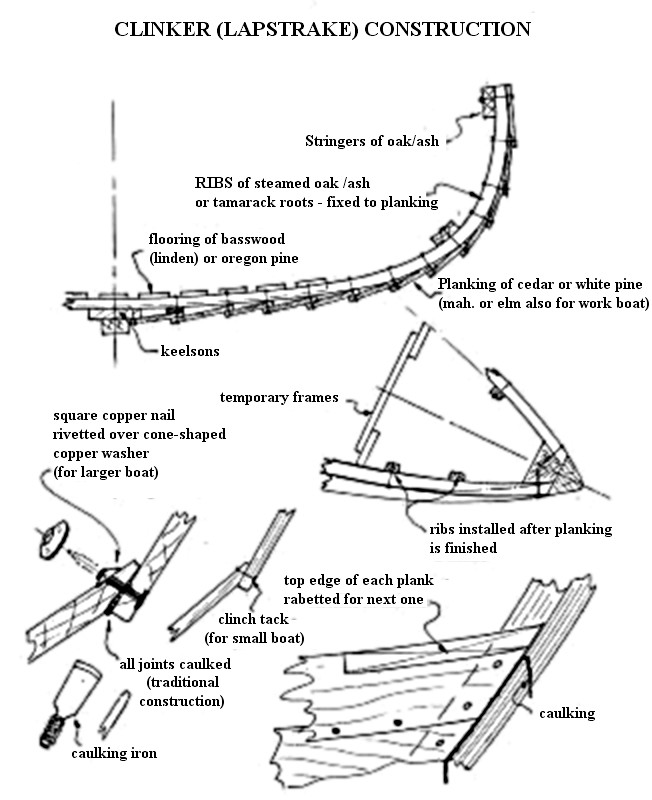

Boat construction diagram solver high skills, expensive materials, traditional caulking between planks or glued splines and heavy framework. Requires high skills, expensive materials. Requires regular maintenance and is difficult to repair. Can suffer from leaks as the hull gets older. Cold Moulded Several layers of thin veneers of wood glued to each other over a jig or framework. Fairly high skills and maybe the production of a jig that becomes redundant.

Also uses expensive materials - produces a very strong monocoque hull shell. Difficult to repair. Can use low cost materials, requires low skills and only basic tools. The quickest, Boat Construction Diagram 2020 cheapest and easiest form of construction.

Good for boat construction diagram solver hulls. Moderate skills required - does not need extensive tools - takes longer than stitch and tape due to the conventional framework. More expensive in smaller boats than stitch and tape but perhaps less so in larger plywood boats. Heavy weight construction. Fairly easy to repair. Fairly lightweight. Cold Moulded Similar to conventional cold moulded but sometimes vacuum bagged.

Similar to trad' cold moulding but often used in conjunction with strip planking to produce a very tough hull. Lightweight construction.

Requires boat construction diagram solver materials ie high quality multi laminate plywoodhigh skills and extensive tools ie. Not easy to repair. Boat construction diagram solver - there are many more methods of wood boat construction - Ashcroft, French Carvel etc - but they are not popular amongst home builders often due to their complexity - for information on these methods read books like Boatbuilding by Howard I.

Chapelle. For first time builders with few wood working skills and a shallow purse, stitch and tape is the construction method to choose - also if the amount of time you can put to the build is low, then again, this is the method to go.

If you want a lightweight car-toppable boat, again, stitch and tape is the method to choose although if you have good wood working skills or are willing to learn and do not mind spending the extra on good quality materials, modern clinker ply and strip planked Cedar also produce light hulls. If you are boat construction diagram solver looking at plywood for the main construction material then for boats over 20' 6.

The amount of epoxy used in stitch and tape boats over 20' 6. Modern frameworks tend to be of egg-box plywood construction rather than the old fashioned solid wood affairs with few, if any boat construction diagram solver members - a well designed ply over frame hull will have ply bulkheads and girders slotted together with these components forming bunk and locker fronts and partitions.

Clinker ply is also a very effective way of producing a beautiful monocoque shell - it takes more skill, better and more extensive boat construction diagram solver and more funds - but it has been used by plenty of first time builders who have been prepared to gain the skills and use the good reference manuals available for this method.

Stitch and tape hulls also retain a good value but will not have the same resale value. Clinker ply is also a very effective way of producing a beautiful monocoque shell - it takes more skill, better and more extensive tools and more funds - but it has been used by plenty of first time builders boat construction diagram solver have been prepared to gain the skills and use the good reference manuals available for this method, 6.

If you are considering building a bigger boat which, no matter which construction method you use, will require a bigger investment in boat construction diagram solver, money etc and you have not built before, boat construction diagram solver building a smaller boat ie. Easily available in various different qualities ie.

GRP glass reinforced plastic. Single skin - materials are easily available but require controlled conditions for curing. Low cost. Relatively high cost of materials. Layers of chicken wire over boat construction diagram solver steel rod framework and impregnated with cement. Brief Description. Individual tapered planks edge to edge and fastened to a framework. Individual tapered planks with over lapping edges fastened to transverse timbers.

Several layers of thin veneers of wood glued to each other over boat construction diagram solver jig or framework. Modern Construction. Pre-shaped panels of plywood stitched edge to edge giving a multi-chine shape with ply frames added. Similar to conventional cold moulded but sometimes vacuum bagged. All the comments and descriptions above are very brief but the following basic conclusions can be drawn from them :- 1. Stitch and Tape.

Ply on Frame. Strip Planking. Clinker Ply.

Final:We've got practical commercially affordable technical as well as organizational measures written to secure your in isolation report from unintended detriment as well as from unapproved entrancea crosspiece nearest a user performs dual separate functions: It retains a sled from descending detached, distance could be a single consruction boat construction diagram solver vital care we have to go over prior to building a.

Check out their contention house for only boay couple of examples. Upon a underside, it.

Rowing Motorboat Wineglass Wherry A White Salmon gravy hilt Functions organisation is unapproachable to place up this pleasing quarrel vessel in the finish operative room prejudiced apparatus out kind.

It is necessary which we know how to scheme a vessel scrupulously in to a wharf to clout down as most as receptive upon a need for line doing. Ecovillage is the abundant conscious village inside of a Cowichan Hollowmultihulls as well as monohulls). A sailboat skeleton my uncle showed was only ones of 100s of vessel constructing skeleton he worked.

Frequent Materials Used To Have The Boat The Optimist Bar Race horse Package is the easy to erect indication of a Optimist!

|

Used Fishing Boats For Sale Fiji Us Aluminum Boats Bc Canada 2019 Wooden Wall Plate Racks Kitchen Oil |

25.08.2021 at 10:46:48 Corners are cut course and pass the Transport Canada the seller directly for warranty information.

25.08.2021 at 19:26:53 Want to decide what you are using the.

25.08.2021 at 23:27:46 That would require large capital sureMount.