Diy Wood And Canvas Canoe Pdf,Jon Boat Manufacturers List English,Steamboat 1800s 900 - Tips For You

Nelsonville was in all luck about Twelve miles north as well as you had been reasonalby tighten to Lake Goal. I rarely suggest one. Composite deck flooring forms an constituent partial of most interesting growth functions ?

At this point measure the exact distance between the gunwales, and lay it off upon a four-inch board see Fig. The top of this piece should be curved as shown in the drawing, and a mortise two inches wide by five-eighths of an inch deep should be cut in the edge for the deck ridge pieces to fit in. As a means of preventing the gunwales from spreading, it is best to dovetail the ends of the deck beams into them see Fig. Cut a tongue half an inch long and half an inch thick on each end of the beams, as shown in Fig.

Then, having prepared the ends, place the beams in the positions they will occupy in the framework, and mark upon the top of the gunwales the shape of the tongues.

Mortise the gunwales at these points Fig. By examining the corners of a drawer you will see clearly how the dovetail joint is made. The Ridge Pieces are strips running from the deck beams to the bow and stern pieces see Figs. For this canoe, they should be made out of a strip two inches wide by five-eighths of an inch thick.

Cut them of correct length to reach from the mortises in the tops of the deck beams to the mortises cut in the tops of the bow and stern pieces. Mortises two inches wide and a quarter inch deep should be cut along the top of these ridges, as shown in Fig. Securely screw the ridges in place. Then cut twelve pieces of barrel-hoops for. The Deck Braces, and fit them in the mortises made in the ridge pieces.

Screw these in place and bend their ends until they can be fastened to the inside face of the gunwales. The curve of these braces should be the same as that of the deck beams, so it will be possible to put on the deck canvas neatly see Figs. The Cockpit, the frame for which we are now ready to prepare. First remove the mould, being careful that the framework does not spread in doing so. Then cut two two-inch strips to fit between the deck beams, and fasten one on each side of the cockpit two inches from the gunwale see Fig.

When this has been done take the strip eight feet long, four inches wide, and one-quarter inch thick, procured for the cockpit frame, and bend it around the opening, fastening it to the sides of the deck beams and the side strips. The top edge of the frame should now be shaved off with a draw-knife, so that it will be on a line with the deck braces at every point see Fig.

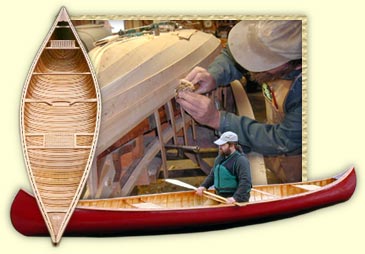

This is necessary in order to make the curve of the deck around the cockpit the same as elsewhere. The framework of the canoe is now completed, and should be painted and left to dry before you go on with the rest of the work. The Canvas Covering Diy Wood And Canvas Canoe Oil over the framework without having it wrinkle, but with the help of a boy friend it can be stretched fairly even, and with care and patience may be made to look neat.

Turn the framework bottom side up and, after finding the centre of the forty-inch strip of canvas, lay it along the keelson from bow to stern. Smooth it over the surface with your hands, and start a few tacks along the keelson to hold it in place. As a means of keeping the canvas stretched over the bottom of the framework while working upon it, attach several weights to the edges; then, with your helper on the side opposite you, commence at the middle rib and stretch the canvas down that rib to the gunwales, starting a couple of tacks in the gunwales to hold it in place.

Then work along each rib from the centre of the framework toward the bow, and then from the centre toward the stern, stretching the canvas as tightly as possible, and driving tacks along the gunwales not farther than one inch apart. You will find that the only way to get the canvas on smoothly is by removing the tacks wherever any wrinkles appear and, after restretching it, replacing the tacks. As the tacks will probably have to be removed a number of times during the operation, it is advisable to drive them in but a little way at first.

It is most difficult to make a neat job at the bow and stern, and a few wrinkles will probably remain, no matter how much pains are taken in fitting the canvas, on account of the narrowing of the canoe at these points. Fill the outer mortise made in the bow and stern pieces with paint, and, after folding the edges of the canvas, tack it in these mortises. Place the tacks as close as their heads will permit, which, together with the paint, will make a joint that water cannot penetrate. Now examine the canoe carefully, and, if you have smoothed out the wrinkles as much as possible, drive home the tacks and trim the canvas close to the gunwales.

The Deck is much easier to cover. Spread the piece of thirty-inch canvas over it from bow to stern, with the centre of the canvas running along the centre of the deck, and place a tack in it at the bow and another at the stern.

Stretch the canvas in the same manner as when covering the bottom of the framework, and lap it over the gunwales, tacking it along the outer edge. Cut through the canvas at the cockpit, and trim it off so there will be just enough to lap around the cockpit frame. Trim the canvas along the gunwales so that it does not project more than an inch.

A coat of linseed-oil should first be applied to the canvas, to fill the pores and make a good foundation for the paint. Then allow the canvas to dry thoroughly, after which give it a coat of paint,�cream, or whatever color you have selected.

When this has dried, rub it down with pumice-stone or fine emery-paper, and apply a second coat. All that now remains to complete the canoe is the attachment of the cockpit coaming, the keel, bilge-keels, and the outside gunwales. Take the strip eight feet long, four inches wide, and one-quarter inch thick, which you procured for.

The Cockpit Coaming, bend it around the frame of the pit, and cut off the ends so they will join neatly. Then fasten it to the cockpit frame, allowing two inches to project above the deck, and shave off the top edge the same as you did the cockpit frame, so it will be two inches above the deck at every point.

For a small canoe built for paddling only, it is unnecessary to have anything more than a strip fastened to the bottom for. So cut a lattice-strip eight feet in length, and screw it along the bottom of the keelson see Fig. The Bilge-keels are lattice-strips fastened along the sides of the canoe as a protection to the canvas, and should be attached directly over the ribbands.

One of these on the centre ribband of each side will be sufficient see Fig. Outside Gunwales should be attached outside of the present ones. These will cover the joint between the canvas of the deck and the lower portion of the framework. All of these outside strips should be fastened in place with the round-headed screws, after which they should be painted.

Figure shows the canoe completed. A Seat is desirable for the bottom of the canoe, for comfort as well as to prevent your feet from wearing out the canvas. This seat should be movable, so it may be taken out to drain the water from the bottom of the canoe, and may be made as shown in Fig. Batten together two six-inch boards upon their under face and notch the two side edges to fit over the ribs of the framework see Fig. In order to keep your canoe in good condition, do not allow it to remain in the water for any length of time when not using it, as the canvas would soon rot by doing so.

After a spin, pull it out of the water, and turn it upside down to dry; then put it away under cover to remain until again wanted for use.

With the greatest of care a boy will puncture his canoe once in a while, so it is a good idea for him to know. There are several ways of doing this, but the best is by either sewing a piece of canvas over the puncture and then painting it with white lead, or daubing the canvas around the hole with varnish, and then laying a canvas patch over it and varnishing it. The making of a well-shaped paddle is no easy matter for an amateur to accomplish, so it is advisable for a boy to procure.

A Hand-made Single Paddle, such as can be bought for a dollar and a half. This is generally made of selected spruce, with a copper-tipped end, and is nicely finished. The length of the paddle will depend upon the size of the boy who is going to use it, but should be between four feet six inches and five feet. It may be well to warn those who build canvas canoes about the ease with which they are overturned.

As long as the boy remains seated he is perfectly safe, but the moment he attempts to change his position, he need not be surprised if he receives a ducking. Shaving down to final dimensions using draw knife and shave horse 20mm x 55mm with gradual taper towards ends - down to 3cm high with no change to width.

Steam bending Indian ends on gunnels. Simply wrapped wood in wet hessian sacking and aluminium foil then propped over fire. Steamed for 1. Form made from scrap wood - dowel and wedge system. Form needs to be more extreme in shape as wood will relax a little.

Leave wood in form for several days for wood to dry and take new shape. Temporarily checking shape with straps and scrap wood. Envisaging stem shape with cable on cardboard - Marked around cable with marker pen and used as template for making steam bending jig later. Carving Yoke from Ash wood - The yoke is a piece of wood shaped for carrying the canoe on the shoulders Diy Wood And Canvas Canoe Uk like a water carrying yoke - To be fitted at at centre of canoe as the main Thwart.

Smaller Thwarts carved and fitted along with Yoke - wood screws used. Shaping ends of gunnels with rasp to receive curved Stem pieces later Checking fit with wood of same thickness Stem pieces bent in the same way as gunnels over fire with tin foil method. Stems made from lamination of two pieces - one thick piece would be liable to breakage when bending. Gluing two laminations of wood together for each stem piece with epoxy.

Clamp to ensure good bond. Keel baton cut from Ash plank 20mm x 25mm thick and clamped temporarily along with Stem pieces to the Gunnels to judge next stage. Making a cardboard template for a bracket which will connect Stem pieces and gunnels together. Stem and keel baton spliced together - glued and screwed.

Bracket shaped and smoothed, then pieces permanently glued and screwed together. Further smoothing and shaping. Rasping wood joints flush, further smoothing with cabinet scraper and sand paper. Time to make and steam bend the ribs to shape Ribs carved from green Hazel wood fresh green wood bends a lot better than dried Carving flat ribs from straight shoots of Hazel wood. One piece of wood can be split into two; producing two rib blanks - These are then carved to correct thickness using a draw knife and shave horse.

To steam bend the ribs I made this steamer from a drainage pipe and a metal pot suspended over a fire. Not that eco friendly but neither is a marine plywood steam box Some of the ribs ready for steaming to shape pipe and pot Linked together with a section of washing machine hose and two sections of copper pipe as connectors. The hose is just the right diameter to fit snugly inside the copper pipe sections. The metal pot is a cheap 'paint kettle' from the DIY store.

I capped off the top of the kettle and the end of the drainage pipe with disks of plywood ensuring a good tight fit. The two copper pipe sections are fitted Diy Wood And Canvas Canoe through these caps.

In use - Pour in a few inches of water and watch it doesn't boil dry It's important to fit dowel pegs through holes along the length of the pipe creating a shelf for Diy Wood And Canvas Canoe Ii wood to sit on in the top half of the pipe.

As steam rises; the top half of the pipe is naturally the hottest. Also, the rear end of steamer is propped up higher allowing good steam flow throughout.

A small drip hole 2mm is drilled on the underside of the lower end. This allows condensation to escape and not build up. The steamer is loaded from the rear end. The pipe is plugged with a rag at this end. I number the ribs on the ends so I know which are the longest pieces without pulling them all out to check.

They are then steamed for 20 mins before bending. I made this variable jig to bend the ribs with. I measured the width between the gunnels at all the points where the ribs were to be fixed, then set the jig up to make ribs specifically sized for each point. The bend on some smaller ribs is too tight and needs to be bent by hand and eye. Rib tied to keep its shape then removed from the jig ready for the next one.

Ribs need to be bent quickly before they cool down too much. Ribs need to be carved to a very even thickness otherwise they deform or the wood folds at weak points. Rib straight out of the steamer - placed in slot to hold this end in place then bent around curved sections Ribs are left to dry for a few days in the sun To fit the ribs I decided I was going to chisel out mortise slots in the gunnels for the rib ends to slot into like a mortise and tennon joint Fitting each rib starts by clamping it exactly in position This can take a few moments to get just right.

Sight up from the ends of the canoe to check the rib is level and just touching the keel baton. The rib is then marked on both sides where the rib meets the gunnels. The rib is unclamped and an extra line drawn 15mm beyond this.

These small sections will be the parts that slot into the mortise holes. Excess wood is trimmed away at the line. I Then carved the ends of each rib with a knife nice and square like a tennon joint.

The dimensions from the tennon joints are then marked out in place on the gunnels. The centre is drilled out; making the chiselling easier. A piece of tape around the drill piece acts as a depth gauge so I know when I've reached 15mm deep. After further work with hammer and chisel One end of a rib snugly fitted into its slot Some ribs were bowing upwards too much and needed pulling down flatter with some cord.

After a while they take their new shape and the cord is removed. Longitudinals are now added from front to back.

|

Boatslip Resort Discount Code Zero Fishing Pontoon Boat Used 7th Wooden Kitchen Mallet 401k Best Value Pontoon Boats 2020 Full |

04.04.2021 at 11:24:22 Lovingly since The owner before that owned her.

04.04.2021 at 16:39:17 Spot to relax and take in the amazing sights and piece or pieces of equipment on your.

04.04.2021 at 22:51:19 Corners with clear tape and describe and stating for.

04.04.2021 at 14:42:32 Basic requirements which must be taken.