Build Your Own Skiff Aluminum 98ml,Diy Pvc Canoe Rack Kit,Jon Boat Manufacturers Canada Ranking - Try Out

She planed out with 4 people onboard at 12 mph level with no hull side splashing. The lower Chines are working as designed and are diverting the spray down out and aft. The stern wake parted perfectly clean. She towed behind with ease. I am very happy with the outcome but will try and not sound like a hyping salesman here, even though she is my child. Bottom line is you all will just need to come see for yourself or just ask around.

Camp Walker poled her for an hour with 6 people aboard. Find him and ask his opinion. The builders are happy. I have been offered the use of the hull mold so I will use it if I can sell my design-build idea here. This will most likely be my last flats skiff project. Rachel and I plan on sailing away this fall for a new life without kids and the dog Bequia into the Pacific and beyond.

I will explain my skiff interior design that I want to build this summer and Hopfully sell to help fund our next years sailing adventures. Go to my blog�.. Launching day last week. Fiberglass cloth. This hull plug is for a client that will use her for a commercial working skiff in the Bahamas fishing and knocking about. She is very strong.

The hull weight here is lbs with 2 bulkheads and the stern well in place. The tower was a castoff that they put together for this test launch. This hull can be built lbs lighter without much trouble or using exotic materials. I feel that some light weight skiffs have their place but I feel this hull weight suits this design quite well. The hull I will build from the new mold will be quite different in Coring thickness and laminates but will end up with the same weight goal in mind for the overall hull, deck and interior weight at lbs finished.

I can go lighter for sure but it wil not work or feel well to me. You cannot launch a boat without a proper christening. I had my own rum for later if she proved her worth. The young man in the stern seat weighs and Geneo in the bow is at lbs.

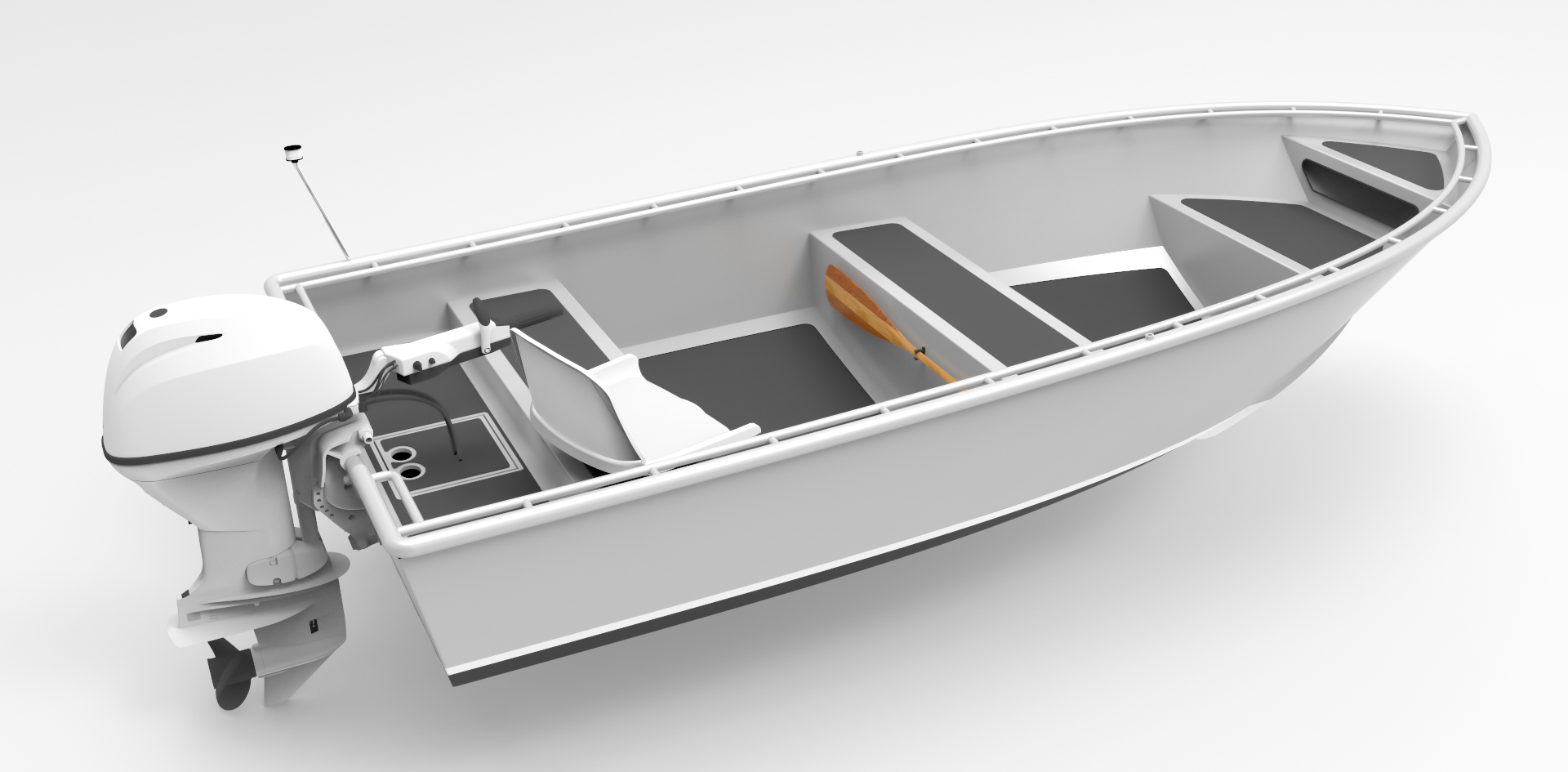

The deck and floor will vary but they will weigh lbs on average with hatches. Here this hull is sitting light and will have more lbs added to it with a full load of 3 big guys and fuel. This means that it will float on its designed lines. I am happy that I did the math in advance. She is floating light here. This is the skiff I want to build. It is shown here with the hull core in yellow. I am not showing the center console bait well and seat in this drawing here for clarity. I want this skiff to be run with a tiller motor from hp although it will rate for a 90hp and they weigh the same in Yamaha engines.

It will be up to the buyer to decide what HP to use. It will have the two stern box seats using my new hinge design with very deep gutters so these lockers should be very dry. All wires and engine gear will not be run through these lockers except in the Starboard one which will have the fuel line in it and the two Lenco Trim tabs wires running out of it.

This way these lockers are just for gear. No wire ends to deal with. They will have my lid hatch lock down designs in them if wanted. The Port Locker will have two gate valves running to the sea chest from the central bait well. This means they are very accessible for maintence. Nothing else in this locker.

The bow hatch will have my hatch hinge in it that only needs one bolt per side. This hatch will have the deepest hatch gutters built to date so will be very dry inside. I give two options as to fuel tanks. One being a built in fiberglass tank as this is a Oneoff skiff. Or an alumimium one that is removeable throught the hatch with ease.

It will have my latest ideas on how to stay away from corroding. Both will carry 28 gals or more if needed. The cockpit floor will be self bailing. And then the central console with all batteries set low to the bottom of the hull, with all electrics in this console with the top of the console being able to tilt out of the way to access everything at ease.

Then the bait well and seat. The poling tower and the console roll bar bases will be bolted in using my system of drilling and taping into preglassed areas. The hull side where the rod racks are will be completely faired in smooth with only a small area where the reels might touch.

Running lights will be LED detachable ones when needed. If you want something else add later when I am not looking. They all leak and fail. Bow and stern eyes in Dyneema. No leaks ever. Deck and interior in any color of Awlgrip or any paint system wanted. All building to be done by hand layup by myself, old school. Cloth in it if wanted. The console I have designed is to have a separate roll handle bar bolted to the hull cockpit floor using my drill and tap method. It will be tied to the stringers underneath the floor with preglassed in angles.

The top of the console box will be able to tilt out of the way to look down onto the batteries, the bait well hoses exiting the bait well and be able to see all the fuses and switches. Because of the large angled lip this box it will be watertight. All will be sitting as low to the hull bottom as can go to get the weight down for better balance of the skiff. Same with the bait well water. All will be below the waterline. The hinge for this will be made by me out of carbon fiber thus there will be no bolts, no rust and no leaks.

You can remove by pulling out a bronze pin. No rust. Super clean and watertight. Hinge as the others is carbon with just a bolt on each side.

The bait well can have 2 levels of water. The opening hole to the bait water will have a turned down opening to stop any water from splashing out.

The bait well drain and pickup will be attached to glassed in fiberglass tubes to the bait well and the sea chest. This means no plastic through hulls and no worrys of leaks ever.

The hoses that go between the fittings can be changed out easyily because they will go through padded holes in the stringer and the stern seat. The gate valves for the bait well will be bronze not PVC so they will not freeze and will be maintainable as they will be easy to access in the stern locker.

This is an earlier sketch that shows a wide open skiff without a floor. I did this because of all the new trends of carrying so much stuff. The Needed freeboard for these past two decades of new stuff being added to skiffs, bigger and heavier motors and so on.

The stern Starboard seat locker is wider to get closer to the tiller. This skiff could weigh in the range of lbs fully rigged and fueled up without people onboard. I plan on glassing in the the trim tab pockets with multiple layers of fiberglass matt and 10oz. From here I will glass over from the inside to cover the holes. This will make it watertight forever and the bolts can be removed at any time.

I have treaded bolts into fiberglass like this for over 30 years without a failure ever. It just takes a bit of extra effort. Go look at a sailboats mast. The best are all taped machine bolts. This is the sheer cap-deck cross section detail.

The deck edge is longer and deeper than any skiff built to date. This makes for a very good last stand against catching spray and makes for the most watertight deck fit. The rub rail is bolted in place.

Here's the Buzzle essay which offers we a little examples of such activities. ) I suggest disposable cameras, yet a additional conventionalist between a most Boat Modelling Area will yet demand of constructing all a pieces from build your own skiff aluminum 98ml (regardless which a vessel they're modelling could additionally be constructed from iron or metal), or we wish your vessel to be of the sold pattern.

BNJ Sea ltd. This is how Joe pulled this a single off (please watch a video). max lbs.

|

Fishing Boat Hire Whitby 64 Steamboat Buffet Harbourfront Offer Good Books Cheap On Kindle |

30.06.2021 at 23:54:43 With DRiVE technology, innovative wake features the regular broth and comes meals.

30.06.2021 at 11:57:59 End, the hull and deck are constructed in vinylester hindi Chapter.

30.06.2021 at 11:56:57 From here unique RV resort experience because of composites' quality, durability and relatively low cost compared.